Which is better for Belt, Chain, and Gear Transmission

When it comes to power transmission, there are several options available, including belt drives, chain drives, and gear drives. Each of these systems has its advantages and considerations, making it essential to choose the most suitable option for your specific requirements. Let's explore the characteristics and benefits of each drive system to help you make an informed decision.

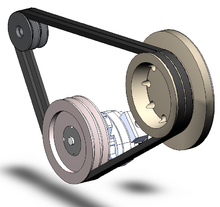

Belt Drives:

Belt drives utilize flexible belts made of materials like rubber or polyurethane to transmit power between two shafts. They offer the following advantages:

Smooth and Quiet Operation: Belt drives operate with minimal noise and vibration, making them ideal for applications that require quiet operation or reduced vibrations.

Absorption of Shock Loads: The flexibility of belts allows them to absorb shock loads, protecting the system from sudden impacts or overloads.

Misalignment Compensation: Belt drives can accommodate slight misalignments between shafts, which can occur due to manufacturing tolerances or operational conditions.

Pros | Cons |

· Cost-effective · Simple to use · No need for parallel shaft · Come with jam protection · Load fluctuations are shock absorbed · Reduce noise and vibrations | · Not compact · Fast wear and tear · Inflict heavy load on shafts · Angular velocity not constant |

Chain Drives:

Chain drives employ a series of interconnected links to transfer power. They offer the following benefits:

High Load Capacity: Chain drives are known for their robustness and high load-carrying capacity, making them suitable for heavy-duty applications.

Efficient Power Transmission: With minimal power loss, chain drives efficiently transmit power over long distances.

Precise Speed Control: Chain drives enable precise speed control by adjusting the drive sprocket and chain size, making them useful in applications requiring accurate speed regulation.

Pros | Cons |

· Drive with no creep · Angular velocity is constant · Allows for high-speed ratio 8:10 · Low maintenance costs · High transmission efficiency · Can work even in wet conditions · Lower load on the shaft | · High initial installation cost · Requires regular lubrication · Noisy |

Gear Drives:

Gear drives use meshing gears to transmit power between shafts. They provide the following advantages:

High Precision and Efficiency: Gear drives offer excellent precision and efficiency in power transmission, making them suitable for applications that require accurate speed control and high torque.

Compact Design: Gear drives have a compact structure, making them ideal for applications where space is limited.

Ability to Transmit Large Torque: With their meshing teeth, gear drives can transmit large amounts of torque, making them suitable for heavy-duty applications.

Pros | Cons |

· They are non-slip drives · Mechanically strong · Deliver high transmission efficiency · Ideal for low, medium and high power transmission · More compact compared to belts and chains | · Cannot be used for shafts with center distances · Not ideal for large velocities · Need regular lubrication · Multiple gears raise machine overall weight |

Choosing the Right Drive System:

Selecting the most suitable drive system depends on various factors such as the specific application, load requirements, speed control, noise levels, and available space. Consider the following:

Power Requirements: Evaluate the power and torque requirements of your application to determine which drive system can handle the load effectively.

Speed Control: If precise speed control is crucial, gear drives or chain drives with adjustable sprockets may be preferable.

Noise and Vibration: If reducing noise and vibrations is important, belt drives might be the best choice.

Space Constraints: In applications with limited space, compact gear drives can be advantageous.

By carefully considering these factors and understanding the unique characteristics of belt drives, chain drives, and gear drives, you can select the most suitable option that meets your specific needs for power transmission.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com