Lumber conveyor chain is widely used for wood factory. The main specification includes 81X,81XH,81XHH,and 3939 lumber conveyor chain. We can supply high quality lumber conveyor chain to satisfy customers' demand.

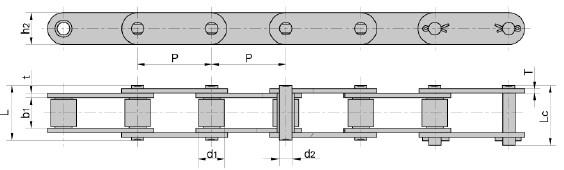

| Chain no. | Pitch | Roller Diameter | Width Between Inner plate | Pin Diameter | Pin Length | Inner Plate depth | Plate thickness | Ultimate Tensile Strength | Average Tensile Strength | Weight Per Meter | |

| p | D1 Max | B1 min | D2 Max | L max | Lc max | H2 max | T | Q Min | Q0 | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | Km/m | |

| 81X | 66.27 | 23.00 | 27.00 | 11.10 | 49.0 | 53.5 | 28.50 | 4.00 | 106.7/24250 | 128.9 | 3.78 |

| 81XH | 66.27 | 23.00 | 27.78 | 11.10 | 60.7 | 65.1 | 31.35 | 7.94/5.55 | 151.9/34523 | 175.7 | 5.88 |

| 81XHH | 66.27 | 23.00 | 27.78 | 11.10 | 65.6 | 70.0 | 31.35 | 7.94 | 191.1/43432 | 212.6 | 6.70 |

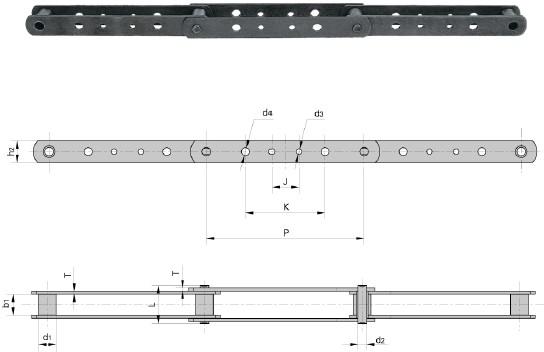

| Chain no. | Pitch | Roller Diameter | Width Between Inner plate | Pin dimension | Plate dimension | Ultimate Tensile Strength | Weight Per Meter | |||||

| p | D1 Max | B1 min | D2 Max | L Max mm | H2 max | D3 max | D4 max | J Max | K Max | Q min | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Km/m | |

| 3939 | 203.2 | 23.00 | 27.00 | 11.1 | 49.0 | 28.58 | 7.2 | 7.2 | 38.1 | 101.6 | 115.58/26268 | 2.45 |

Applications of Lumber Conveyor Chain

Lumber conveyor chains, also known as lumber chains or mill chains, are specialized conveyor systems designed for transporting logs, lumber, and other wood products within sawmills, lumber yards, and wood processing facilities. These chains are well-suited for heavy-duty applications in the timber industry. Here are some common applications of lumber conveyor chains:

Log Decks: Lumber conveyor chains are often used on log decks to transport raw logs from one processing area to another. They can handle the weight and size of large logs efficiently and are designed to withstand the rough environment of a sawmill.

Log Turner Conveyors: In sawmills, log turners are used to reposition logs for optimal cutting. Lumber conveyor chains play a crucial role in moving the logs to and from the log turner, ensuring a continuous and automated process.

Primary Breakdown Process: Lumber conveyor chains are employed to move logs through various stages of the primary breakdown process, which involves cutting logs into rough boards, cants, and flitches. These chains help transport the wood through multiple cutting and processing machines.

Edgers and Gang Saws: Edgers and gang saws are used to further process rough lumber by trimming the edges and cutting it into smaller pieces. Lumber conveyor chains facilitate the movement of lumber through these machines, ensuring accurate cutting and efficient processing.

Sorting and Grading: After cutting and processing, lumber conveyor chains transport the different grades and sizes of lumber to sorting and grading areas. This allows for efficient categorization and distribution of lumber based on quality and specifications.

Kilns and Drying Chambers: Lumber chains can be used to move lumber through drying kilns or chambers, where the moisture content of the wood is reduced. Proper airflow and even drying are essential to prevent warping and ensure the quality of the dried lumber.

Lumber Stacking and Packaging: Once processed and dried, lumber is often stacked and bundled for storage or transportation. Lumber conveyor chains can assist in moving stacks of lumber to packaging stations, where they are bound together and prepared for shipment.

Wood Residue Handling: In some cases, lumber conveyor chains are used to transport wood chips, sawdust, and other wood residues generated during the processing stages. These residues may be collected and repurposed for various applications, such as biomass fuel or wood-based products.

Lumber conveyor chains are designed to withstand heavy loads, harsh conditions, and continuous operation. They are built with durable materials and precise engineering to ensure the efficient movement of wood products throughout the entire wood processing cycle. Proper maintenance and lubrication are crucial to ensure the longevity and reliable performance of these chains in the timber industry.