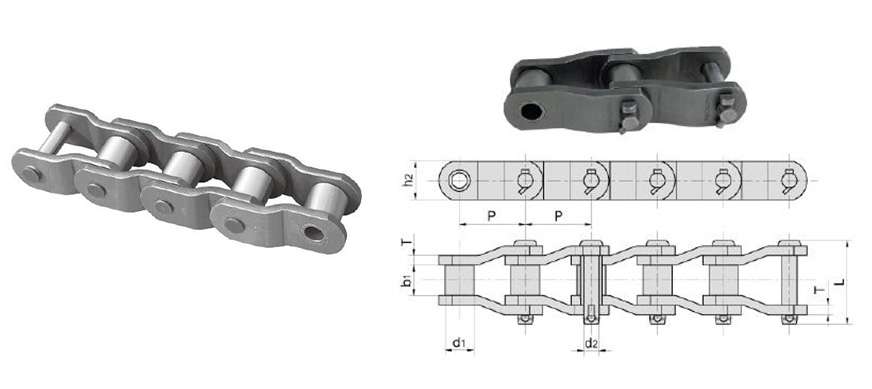

Heavy-duty cranked-link chain is famous for its high accuracy, resistance to wear and fatigue durability. Its specific cranked-link joint structure is more suitable for the work environment with larger impact load and frequently changed intermittence. It mainly is used for large equipment and power transmission under heavy working conditions in mining, metallurgy, and engineering machinery industries.

Heavy duty cranked-link chain offered by us are manufactured from high quality special heat treated steel alloys. Durable in quality, these heavy duty cranked link chains have long service life. These chains are offered with the facility of length tolerances and lateral clearances that helps it to operate over flame cut or cast tooth sprockets. The main specification includes 2010,2512,2814,3315,3618,4020,4824 etc.

| Chain no. | Pitch | Roller Diameter | Width Between Inner plate | Pin Diameter | PinLength | Plate depth | Plate thickness | Ultimate Tensile Strength | Average Tensile Strength | WeightPer Meter |

| p | D1Max | B1min | D2Max | LMax | H2 | T | QMin | Q0 | q | |

| mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | Km/m | |

| 2010 | 63.50 | 31.75 | 38.1 | 15.90 | 90.70 | 47.80 | 7.90 | 250.0/56818 | 270.00 | 13.53 |

| 2512 | 77.90 | 41.28 | 39.6 | 19.08 | 103.40 | 60.50 | 9.70 | 340.0/77272 | 367.20 | 18.40 |

| 2814 | 88.90 | 44.45 | 38.1 | 22.25 | 117.60 | 60.50 | 12.70 | 471.0/105955 | 507.60 | 25.70 |

| 3315 | 103.45 | 45.24 | 49.3 | 23.85 | 134.90 | 63.50 | 14.20 | 550.0/125000 | 594.00 | 27.71 |

| 3618 | 114.30 | 57.15 | 52.3 | 27.97 | 141.20 | 79.20 | 14.20 | 760.0/172727 | 820.80 | 41.20 |

| 4020 | 127.00 | 63.50 | 69.9 | 31.78 | 168.10 | 91.90 | 15.70 | 987.0/224300 | 1069.20 | 48.60 |

| 4824 | 152.40 | 76.20 | 76.2 | 38.13 | 187.50 | 104.60 | 19.00 | 1600.0/363632 | 1700.00 | 69.80 |

HEAVY DUTY ANSI ROLLER CHAINS

The heavy duty chain is manufactured with thicker inner and outer link plates over standard chains. This slight improves increases the chains working load and fatigue resistance while enduring more frequent & heavier shock loads. Heavy series chain is a great option for mechanical engineers designing drives that require more strength, but restricted to tight space requirements. These chains are readily available in single strand, double strand and triple strand options. We offer two styles, which is your standard riveted and cottered construction.

Heavy Duty Chain Common Uses

Typically heavy series roller chains is best suited for drives that have moderate loads, frequent starting/stopping or forward/reverse directional changes. Below are just a some examples of common everyday uses for our heavy series chain.

Agricultural Equipment

Lumber Industry

Construction Equipment

Heavy Duty Conveying Systems

Heavy Duty Roller Chain vs Standard Roller Chain

First off, both chains are recognized as ANSI B29.1 industry size roller chains. The dimensions are very similar except heavy duty chains do have thicker plates, which makes the chain wider. With heavy duty roller chain you gain both working load strength and greater fatigue resistance. Standard chains are better for smoother operations with lighter loads, whereas heavy duty can handle heavier loads and more repetitive shock load.