Double pitch roller chain, also referred as extended pitch conveyor roller chains, are built in accordance with ANSI B29.4. Products with attachments are widely used in conveyor applications when loads are low and speeds are moderate. Available variations include larger diameter rollers and hollow pin design. These chains can also be supplied in stainless steel, nickel-plated or zinc-plated versions (oversized roller chain can be steel or engineering plastics).The main specification includes C2040,C2042,C2050,C2052,C2060H,C2062H,C2080,C2082,C2080H,C2082H etc.

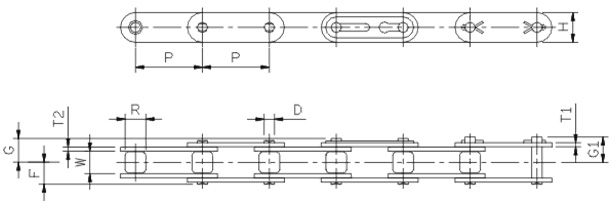

| CHAIN NO. (ANSI) | Pitch | Width | Roller | Plate | Pin | Average Ultimate Strength kgf | Approx Weight kg/m | |||||||

| P | W | Dia | Height | Thickness | Dia | Lengths | ||||||||

| inch | mm | mm | R | H1 | H2 | T1 | T2 | D | F | G | G1 | |||

| A2040 | 1" | 25.40 | 7.94 | 7.92 | 10.10 | 11.70 | 1.50 | 1.50 | 3.96 | 8.20 | 9.35 | 10.10 | 1850 | 0.40 |

| A2050 | 1-1/4" | 31.75 | 9.53 | 10.16 | 12.60 | 14.60 | 2.00 | 2.00 | 5.06 | 10.10 | 11.65 | 12.60 | 3100 | 0.66 |

| A2060 | 1-1/2" | 38.10 | 12.70 | 11.91 | 15.00 | 17.10 | 2.40 | 2.40 | 5.95 | 12.50 | 14.15 | 15.40 | 4400 | 0.93 |

| CHAIN NO. (ANSI) | Pitch | Width | Roller | Plate | Pin | Average Ultimate Strength kgf | Approx Weight kg/m | ||||||

| P | W | Dia | Height | Thickness | Dia | Lengths | |||||||

| inch | mm | mm | R | H | T1 | T2 | D | F | G | G1 | |||

| C2040 | 1" | 25.40 | 7.94 | 7.92 | 11.70 | 1.50 | 1.50 | 3.96 | 8.20 | 9.35 | 10.10 | 1850 | 0.49 |

| C2050 | 1-1/4" | 31.75 | 9.53 | 10.16 | 14.60 | 2.00 | 2.00 | 5.06 | 10.10 | 11.65 | 12.60 | 3100 | 0.84 |

| C2060H | 1-1/2" | 38.10 | 12.70 | 11.91 | 17.10 | 3.10 | 3.10 | 5.95 | 14.10 | 15.70 | 16.60 | 4400 | 1.45 |

| C2080H | 2" | 50.80 | 15.88 | 15.88 | 23.00 | 3.90 | 3.90 | 7.94 | 17.90 | --- | 20.80 | 8000 | 2.41 |

| C2100H | 2-1/2" | 63.50 | 19.05 | 19.05 | 28.90 | 4.70 | 4.70 | 9.52 | 21.70 | --- | 24.90 | 12000 | 3.50 |

| C2120H | 3" | 76.20 | 25.40 | 22.20 | 35.00 | 5.60 | 5.60 | 11.10 | 26.98 | --- | 30.57 | 16000 | 6.00 |

| C2160H | 4" | 101.60 | 31.75 | 28.58 | 48.00 | 7.20 | 7.20 | 14.28 | 34.15 | --- | 38.85 | 27500 | 8.90 |

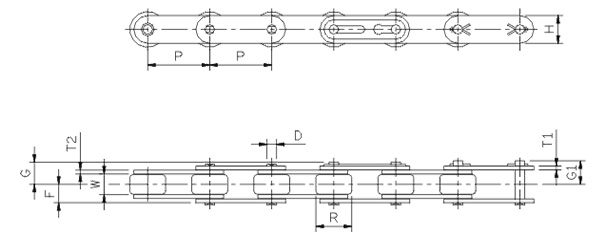

Double Pitch Roller Chain (Oversized Roller)

CHAIN NO. | Pitch | Width | Roller | Plate | Pin | Average | Approx Weight | ||||||

P | W | Dia | Height | Thickness | Dia | Lengths | |||||||

inch | mm | mm | R | H | T1 | T2 | D | F | G | G1 | |||

C2042 | 1" | 25.40 | 7.94 | 15.88 | 11.70 | 1.50 | 1.50 | 3.96 | 8.20 | 9.35 | 10.10 | 1850 | 0.86 |

C2052 | 1-1/4" | 31.75 | 9.53 | 19.05 | 14.60 | 2.00 | 2.00 | 5.06 | 10.10 | 11.65 | 12.60 | 3100 | 1.32 |

C2062H | 1-1/2" | 38.10 | 12.70 | 22.23 | 17.10 | 3.10 | 3.10 | 5.95 | 14.10 | 15.70 | 16.60 | 4400 | 2.17 |

C2082H | 2" | 50.80 | 15.88 | 28.58 | 23.00 | 3.90 | 3.90 | 7.94 | 17.90 | --- | 20.80 | 8000 | 2.87 |

C2102H | 2-1/2" | 63.50 | 19.05 | 39.67 | 28.90 | 4.70 | 4.70 | 9.52 | 21.70 | --- | 24.90 | 12000 | 4.68 |

C2122H | 3" | 76.20 | 25.40 | 44.45 | 35.00 | 5.60 | 5.60 | 11.10 | 26.98 | --- | 30.57 | 16000 | 8.00 |

C2162H | 4" | 101.60 | 31.75 | 57.15 | 48.00 | 7.20 | 7.20 | 14.28 | 34.15 | --- | 38.85 | 27500 | 13.6 |

What is a Double Pitch Chain?

Generally, conveyor chains are operated for longer distances and at decrease speeds than transmission chains. Accordingly, although the pins, bushings and rollers are left unchanged, and the plate pitch is doubled to reduce the amount of sprocket teeth engaged using the chain to half, the wear of pins, bushings and rollers is little because the chain pace is very low. Double Pitch Chains, conform to ANSI normal and “Ultimate Daily life Chain Series” and “Environment Resistant Chain Series”, as are single pitch chains may also be out there.

Double pitch chain with resin rollers.

This is a Double Pitch Chain with R Roller made of resin, which generates much less noise and lighter fat in contrast with steel rollers. Thus, the chain is suitable for a conveyor process designed to operate quietly and convey light-weight posts. Because the components other than rollers are manufactured from steel, the typical tensile power of the resin roller chain would be the very same as that of a steel roller chain. Nevertheless, the “maximum allowable load” in the chain need to be kept lower, as proven while in the following table, to stop harm to your plastic rollers by the pressure through the engagement with sprockets.

The “Allowable load of resin rollers” refers for the allowable load acting when conveyed posts press the resin rollers traveling over the floor surface such as guid rails.

Massive roller (R) and smaller rollers (S)

Considering the fact that double pitch chains are often utilised for conveying items on a horizontal floor, chains intended for this purpose have increased roller diameter equal to that of single pitch chains on the exact same pitch for improved load capacity and reduce traveling resistance. These rollers with more substantial outer diameter are referred to as “large rollers”, along with the standard rollers are termed “small rollers”.

On this catalog, big rollers are expressed as R Roller, and modest rollers as S Roller.

Designation of double pitch chains

A double pitch chain is designated, as in the following illustration, dependant on the nominal number of the single pitch chain it really is based upon.

Connecting links

For that connecting links of double pitch chains of all sizes, the connecting plates and connecting pins are clearance-fitted. For C2060H or smaller sized, the spring clip sort (R connecting link) is standard. For C2080H or greater, the cotter type (C connecting link) is regular. Connecting links with an attachment, top rated roller or side roller may also be out there.

What is a double pitch chain used for?

Double Pitch Roller Chain is a cost-efficient option for lighter applications, as it is manufactured to have twice the pitch of a standard roller chain, reducing the overall weight of the chain and the price

1. Double pitch chains are often used for conveying items on a horizontal floor, and chains intended for this purpose have increased roller diameter equal to that of single pitch chains on the exact same pitch for improved load capacity and reduced traveling resistance

2. Double pitch sprockets are used in conveyor systems that require precise product placement

3. Double Pitch Conveyor Series chains are ideally suited for light to medium duty material handling applications

4.Double Pitch Conveyor Series chains are ideally suited for light to medium duty material handling applications. These chains are similar to standard chain, except the plates are straight and the pitch is twice as long.

Double pitch hollow pin roller chains are normally only available in a version with straight plates as a bush or roller chain. One of the main advantages here is that thelonger pitch allows transport rollers to be fitted, which in many applications significantly reduces friction and tensile forces within the chain.

1. The accessories for single-pitch Conveyor Chains are mainly installed on A series chains, which derive conveyor chains with a pitch of 12.7-50.8 and an "eight"-shaped chain plate. The chain uses rollers to support rolling on the track. Due to the small diameter of the rollers, the load-bearing capacity and transmission efficiency are not as good as the large rollers, so it is only suitable for small conveyors with light load and short conveying distance. However, the conveying speed can be higher, the beat precision of conveying is better, and the overall structure is relatively compact.

2. Double-pitch chains and sprockets for transmission and conveying are suitable for general mechanical transmission or double-pitch chains for conveying, with a pitch of 25.4-76.2mm. The double-pitch chain is a light chain derived from doubling the pitch specified by the short-pitch chain. As a conveyor chain, it has three characteristics in structure than a Transmission Chain: (1) The shape of the chain piece is not a figure 8 but it is straight (2) The end of the chain plate is fan-shaped, not a semicircle (3) The roller is enlarged The large roller set has high load carrying capacity and transmission efficiency.

The difference between single pitch Roller chain and double pitch roller chain;

Roller chain is divided into single-pitch roller chains and double-pitch roller chains. People often do not know the difference between single-pitch roller chains and double-pitch roller chains in daily production. Let's take a closer look.

1. The standard transmission roller chain is a universal transmission roller chain based on JIS and ANSI specifications.

2. Plate chain is a hanging chain composed of chain plates and pin shafts.

3. Stainless steel chains are stainless steel chains that can be used in special environments such as medicine, water, and high temperature.

4. Anti-rust chain is a chain with a nickel plated surface.

5. The standard accessory chain is a chain with accessories attached to the standard roller chain for transmission.

6. Hollow pin shaft chains are chains connected by hollow pin shafts, and accessories such as pin shafts, cross rods and the like can be freely attached or removed according to customer requirements.

7. Double pitch roller chain (Type A) is a chain with 2 pitches of standard roller chain based on JIS and ANSI specifications. It is a low-speed transmission chain with light weight and average length and is suitable for devices with long distance between shafts.

8. Double pitch roller chain (type C) is a chain with 2 pitches of standard roller chain based on JIS and ANSI specifications. It is mainly used for low-speed transmission and transportation. It has standard diameter S-type rollers and large diameter R-type rollers.

9. Double-pitch accessory roller chain is a chain with accessories attached to the double-pitch roller chain, which is mainly used for transportation.

10. ISO-B roller chain is a roller chain based on ISO 606-B. Britain, France, Germany and other places import more products of this type.