For food handling conveyors, Hollow Pin Chains are available in ANSI standard short pitch series (40HP - 80HP), double pitch series with standard rollers (C2040HP - C2080HP), and large rollers (C2042HP - C2082HP). Attachments or cross-rods can be inserted at any desired spacing, which provided great design versatility. Changes can be made without removing the chain from the conveyor. Our Hollow pin chains are as following items:

1. Hollow pin conveyor chains(MC series)

2. Hollow pin conveyor chains(FVC series)

3. Non-standard hollow pin conveyor chains

4. Hollow pin conveyor chains(ZC series)

5. Hollow pin chains

6. Stainless steel hollow pin chains

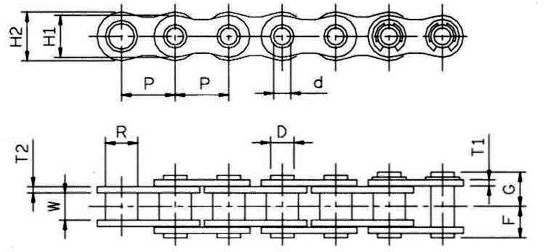

| CHAIN NO. (ANSI) | Pitch | Width | Roller | Plate | Pin | Average Ultimate Strength kgf | Approx Weight kg/m | |||||||

| P | W | Dia | Height | Thickness | Dia | Lengths | ||||||||

| inch | mm | mm | R | H1 | H2 | T1 | T2 | D | d(min) | F | G | |||

| 40HP | 1/2" | 12.70 | 7.94 | 7.92 | 10.20 | 11.80 | 1.50 | 1.50 | 5.58 | 4.00 | 7.90 | 9.4 | 1300 | 0.5 |

| 50HP | 5/8" | 15.875 | 9.53 | 10.16 | 13.00 | 14.80 | 2.00 | 2.00 | 7.01 | 5.12 | 9.90 | 11.65 | 2000 | 0.8 |

| 60HP | 3/4" | 19.05 | 12.70 | 11.91 | 15.50 | 17.50 | 2.40 | 2.40 | 8.12 | 5.99 | 12.40 | 14.25 | 3050 | 1.18 |

| 80HP | 1" | 25.40 | 15.88 | 15.88 | 20.80 | 24.00 | 3.10 | 3.10 | 11.27 | 8.02 | 16.30 | 17.75 | 5800 | 2.10 |

| 08BHP | 1/2" | 12.70 | 7.75 | 8.51 | 10.60 | 11.80 | 1.50 | 1.50 | 6.11 | 4.50 | 8.20 | 9.30 | 1500 | 0.63 |

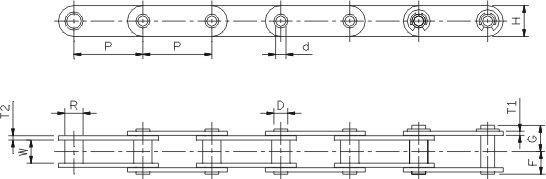

Double Pitch Hollow Pin Chain

| CHAIN NO. (ANSI) | Pitch | Width | Roller | Plate | Pin | Average Ultimate Strength kgf | Approx Weight kg/m | ||||||

| P | W | Dia | Height | Thickness | Dia | Lengths | |||||||

| inch | mm | mm | R | H | T1 | T2 | D | d(min) | F | G | |||

| C2040HP | 1" | 25.40 | 7.94 | 7.92 | 11.70 | 1.50 | 1.50 | 5.58 | 4.00 | 7.90 | 9.40 | 1300 | 0.45 |

| C2050HP | 1-1/4" | 31.75 | 9.53 | 10.16 | 14.60 | 2.00 | 2.00 | 7.01 | 5.12 | 9.90 | 11.65 | 2000 | 0.74 |

| C2060HP | 1-1/2" | 38.10 | 12.70 | 11.91 | 17.10 | 2.40 | 2.40 | 8.12 | 5.99 | 12.40 | 14.25 | 3050 | 1.10 |

| C2080HP | 2" | 50.80 | 15.88 | 15.88 | 23.00 | 3.10 | 3.10 | 11.27 | 8.02 | 16.30 | 17.75 | 5800 | 1.95 |

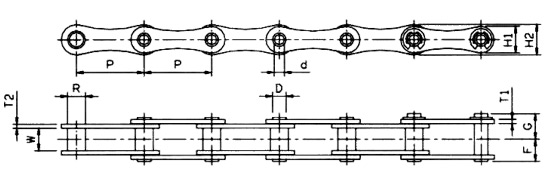

| CHAIN NO. (ANSI) | Pitch | Width | Roller | Plate | Pin | Average Ultimate Strength kgf | Approx Weight kg/m | |||||||

| P | W | Dia | Height | Thickness | Dia | Lengths | ||||||||

| inch | mm | mm | R | H1 | H2 | T1 | T2 | D | d(min) | F | G | |||

| A2040HP | 1" | 25.40 | 7.94 | 7.92 | 10.10 | 11.70 | 1.50 | 1.50 | 5.58 | 4.00 | 7.90 | 9.40 | 1300 | 0.43 |

| A2050HP | 1-1/4" | 31.75 | 9.53 | 10.16 | 12.60 | 14.60 | 2.00 | 2.00 | 7.01 | 5.12 | 9.90 | 11.65 | 2000 | 0.72 |

HP chain standard is rollerless,R indicates bushing diameter.

Hollow pin roller chain is used in a wide range of applications ranging from light to medium conveying applications, drive applications, bakeries, circuit board manufacturing, elevating conveyors, as well as many more.

VS.

VS.

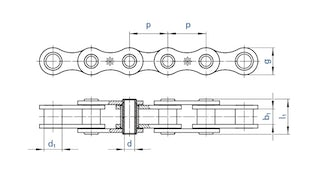

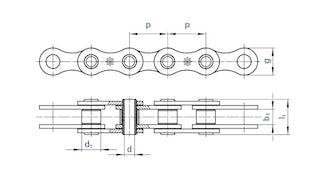

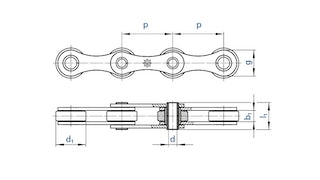

Hollow pin roller chain is a manufactured using a wide one piece solid bushings. This unique design allows for special attachments, pins & other various components to be inserted directly through the hollow pin chain. All hollow pin chains run on the same ANSI sprockets as the ANSI & conveyor chains.

Type 1 is like a bush chain, in favor of the hollow pins the rollers are replaced.

Type 2 is basically a plate chain with a roller, but it has a hollow pin instead of a bushing. Therefore the wear-relevant bearing area is quite small.

Type 3 corresponds to a roller chain with the roller diameter exceeding the plate height. The rollers are manufactured of steel or PA 6.6, and a stainless steel version can also be supplied.

Small and lightweight, often using two parallel chains on small conveyors without bushings, the hollow pin chain is used in a wide range of industrial applications. Used as a carrier in chip conveyors, roller belt systems and bucket elevators, the chains allow easy assembly and disassembly of attachments. Cross bars can be placed on any link without the need to disassemble the chain.

Hollow pin chains, which can be used in different application areas including conveyors, packaging machines and material handling systems, enable smooth operation of work processes thanks to their light weight and strength.