Automobile production line conveyer chain is usde for automobile production line. We has more than 12 years of experience in providing assemblies for the automobile production line and has leading technical superiority in the field of conveyer chain. For 12 years, we have provided numerous automobile production line conveyer chains for Beijing HYUNDAI, Mazda and so on, especially the spraying line chain, which can run reliably for a long time in temperatures up to 300°C, and has a long service life.

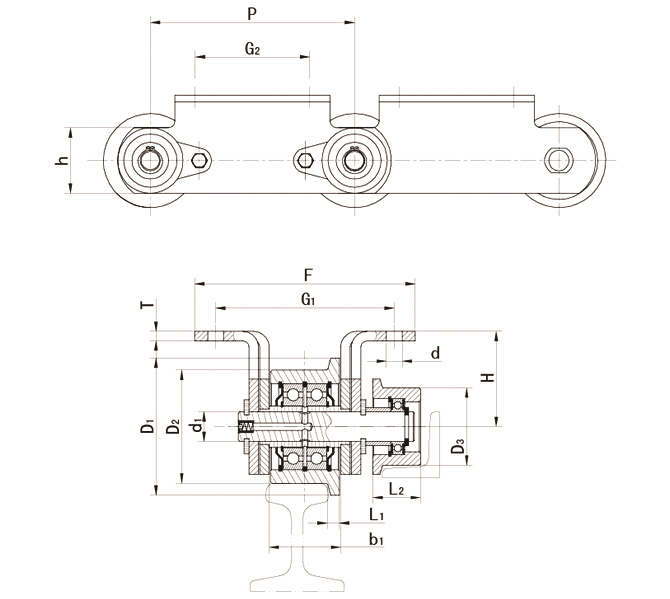

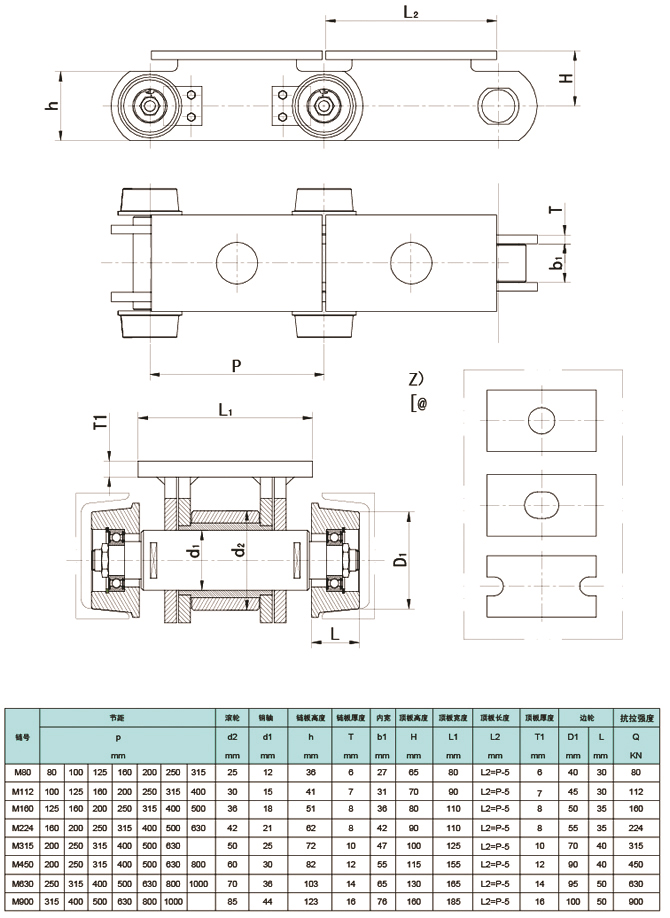

| Model | Pitch | Roller | Pin | Plate Height | Plate Thickness | Width Between Inner Plate | Attachment Height | Bending Height | Attachment Hole Distance | Hole Distance | Side Roller | Stregth | ||||||||||||

| P mm | D1 mm | D2 mm | L mm | d1 mm | h mm | T mm | b1 mm | H mm | F mm | G1 |

|

|

| d mm | D3 mm | L2 mm | Q KN | |||||||

| M80 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 65 | 50 | 6 | 12 | 36 | 6 | 27 | 65 | 160 | 96 |  |  |  | 11 | 40 | 30 | 80 |

| M112 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | 75 | 60 | 7 | 15 | 41 | 7 | 31 | 70 | 184 | 110 |  |  |  | 14 | 40 | 30 | 112 |

| M160 | 125 | 160 | 200 | 250 | 315 | 400 | 500 | 90 | 70 | 8.5 | 18 | 51 | 8 | 36 | 80 | 200 | 124 |  |  |  | 14 | 45 | 35 | 160 |

| M224 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 105 | 85 | 10 | 21 | 62 | 8 | 42 | 90 | 228 | 140 |  |  |  | 18 | 50 | 35 | 224 |

| M315 | 200 | 250 | 315 | 400 | 500 | 630 | 125 | 100 | 12 | 25 | 72 | 10 | 47 | 100 | 250 | 160 |  |  |  | 18 | 70 | 40 | 315 | |

| M450 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 150 | 120 | 14 | 30 | 82 | 12 | 55 | 115 | 280 | 180 |  |  |  | 18 | 75 | 40 | 450 |

| M630 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 175 | 140 | 16 | 36 | 103 | 14 | 65 | 130 | 380 | 230 |

|  |  | 24 | 90 | 50 | 630 |

| M900 | 315 | 400 | 500 | 630 | 800 | 1000 | 210 | 170 | 18 | 44 | 123 | 16 | 76 | 160 | 480 | 280 |  |  |  | 30 | 90 | 50 | 900 | |

0

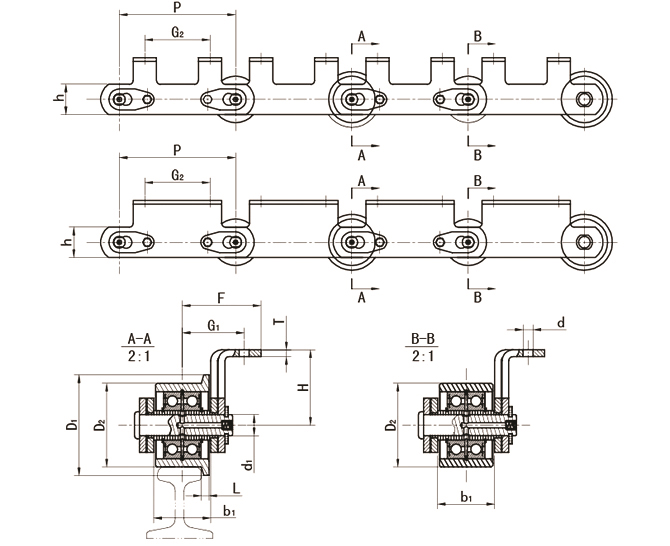

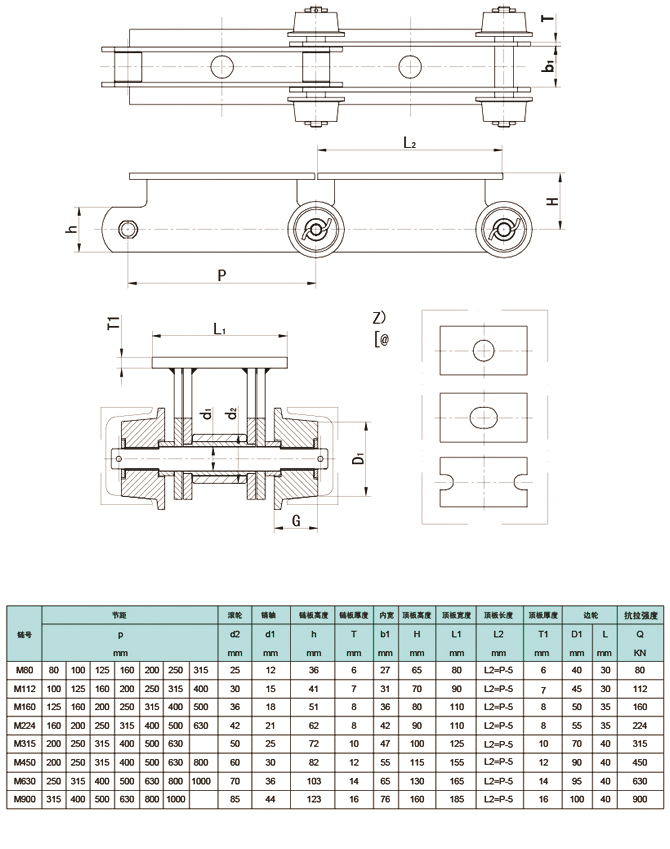

| Model | Pitch | Roller | Pin | Plate Height | Plate Thickness | Width Between Inner Plate | Attachment Height | Bending Height | Attachment Hole Distance | Hole Distance | Stregth | |||||||||||

| P mm | D1 mm | D2 mm | L mm | d1 mm | h mm | T mm | b1 mm | H mm | F mm | G1 |

|

|

| d mm | Q KN | |||||||

| M80 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 65 | 50 | 6 | 12 | 36 | 6 | 27 | 65 | 80 | 48 |  |  |  | 11 | 80 |

| M112 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | 75 | 60 | 7 | 15 | 41 | 7 | 31 | 70 | 82 | 55 |  |  |  | 14 | 112 |

| M160 | 125 | 160 | 200 | 250 | 315 | 400 | 500 | 90 | 70 | 8.5 | 18 | 51 | 8 | 36 | 80 | 100 | 62 |  |  |  | 14 | 160 |

| M224 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 105 | 85 | 10 | 21 | 62 | 8 | 42 | 90 | 114 | 70 |  |  |  | 18 | 224 |

| M315 | 200 | 250 | 315 | 400 | 500 | 630 | 125 | 100 | 12 | 25 | 72 | 10 | 47 | 100 | 125 | 80 |  |  |  | 18 | 315 | |

| M450 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 150 | 120 | 14 | 30 | 82 | 12 | 55 | 115 | 140 | 90 |  |  |  | 18 | 450 |

| M630 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 175 | 140 | 16 | 36 | 103 | 14 | 65 | 130 | 190 | 115 |

|  |  | 24 | 630 |

| M900 | 315 | 400 | 500 | 630 | 800 | 1000 | 210 | 170 | 18 | 44 | 123 | 16 | 76 | 160 | 240 | 140 |  |  |  | 30 | 900 | |

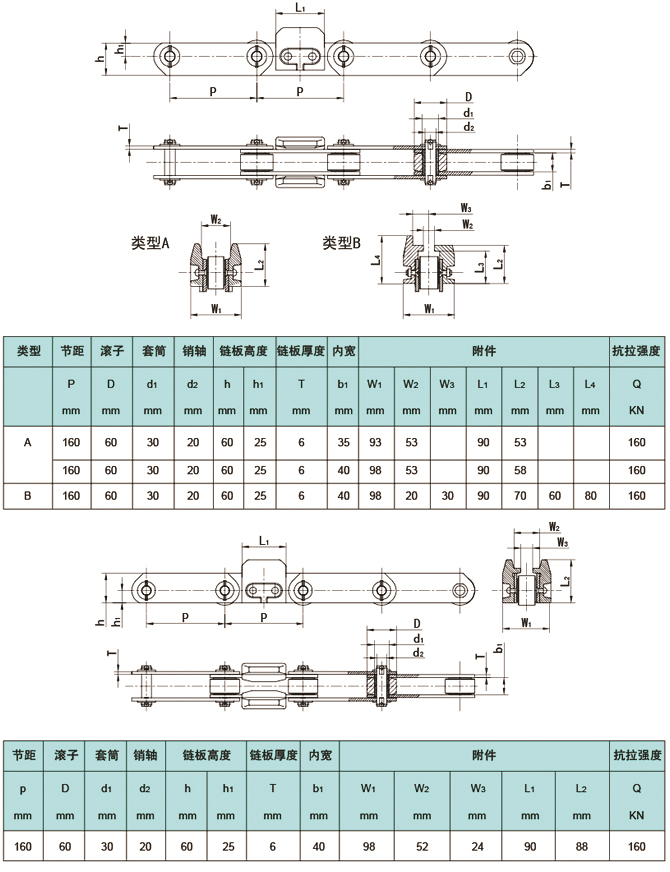

| Model | Pitch | Roller | Pin | Plate Height | Plate Thickness | Width Between Inner Plate | Attachment Height | Bending Height | Attachment Hole Distance | Hole Distance | Stregth | |||||||||||

| P mm | D1 mm | D2 mm | L mm | d1 mm | h mm | T mm | b1 mm | H mm | F mm | G1 |

|

|

| d mm | Q KN | |||||||

| M80 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 65 | 50 | 6 | 12 | 36 | 6 | 27 | 65 | 45 | 25 |  |  |  | 11 | 80 |

| M112 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | 75 | 60 | 7 | 15 | 41 | 7 | 31 | 70 | 55 | 30 |  |  |  | 14 | 112 |

| M160 | 125 | 160 | 200 | 250 | 315 | 400 | 500 | 90 | 70 | 8.5 | 18 | 51 | 8 | 36 | 80 | 55 | 35 |  |  |  | 14 | 160 |

| M224 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 105 | 85 | 10 | 21 | 62 | 8 | 42 | 90 | 60 | 35 |  |  |  | 18 | 224 |

| M315 | 200 | 250 | 315 | 400 | 500 | 630 | 125 | 100 | 12 | 25 | 72 | 10 | 47 | 100 | 60 | 40 |  |  |  | 18 | 315 | |

| M450 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 150 | 120 | 14 | 30 | 82 | 12 | 55 | 115 | 72 | 50 |  |  |  | 18 | 450 |

| M630 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 175 | 140 | 16 | 36 | 103 | 14 | 65 | 130 | 90 | 60 |

|  |  | 24 | 630 |

| M900 | 315 | 400 | 500 | 630 | 800 | 1000 | 210 | 170 | 18 | 44 | 123 | 16 | 76 | 160 | 110 | 70 |  |  |  | 30 | 900 | |

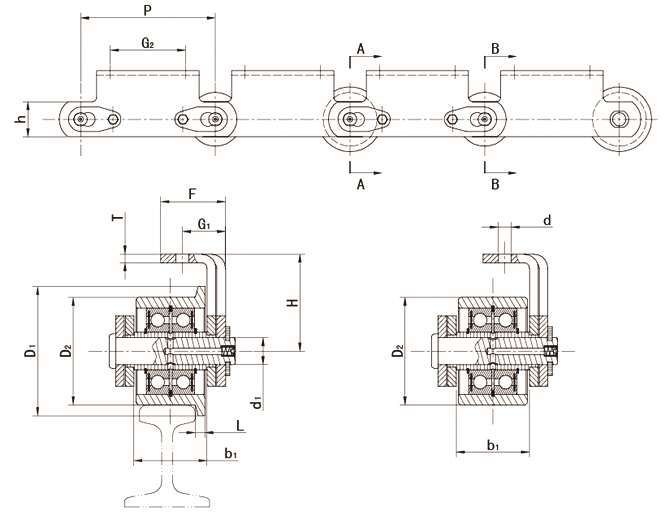

| Model | Pitch | Roller | Pin | Plate Height | Plate Thickness | Width Between Inner Plate | Attachment Height | Bending Height | Attachment Hole Distance | Hole Distance | Side Roller | Stregth | ||||||||||

| P mm | d2 mm | d1 mm | h mm | T mm | b1 mm | H mm | F mm | G1 |

|

|

| d mm | D3 mm | L2 mm | Q KN | |||||||

| M80 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 25 | 12 | 36 | 6 | 27 | 65 | 160 | 96 |  |  |  | 11 | 35 | 30 | 80 |

| M112 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | 30 | 15 | 41 | 7 | 31 | 70 | 184 | 110 |  |  |  | 14 | 40 | 30 | 112 |

| M160 | 125 | 160 | 200 | 250 | 315 | 400 | 500 | 36 | 18 | 51 | 8 | 36 | 80 | 200 | 124 |  |  |  | 14 | 45 | 35 | 160 |

| M224 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 42 | 21 | 62 | 8 | 42 | 90 | 228 | 140 |  |  |  | 18 | 50 | 35 | 224 |

| M315 | 200 | 250 | 315 | 400 | 500 | 630 | 50 | 25 | 72 | 10 | 47 | 100 | 250 | 160 |  |  |  | 18 | 70 | 40 | 315 | |

| M450 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 60 | 30 | 82 | 12 | 55 | 115 | 280 | 180 |  |  |  | 18 | 90 | 40 | 450 |

| M630 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 70 | 36 | 103 | 14 | 65 | 130 | 380 | 230 |

|  |  | 24 | 95 | 50 | 630 |

| M900 | 315 | 400 | 500 | 630 | 800 | 1000 | 85 | 44 | 123 | 16 | 76 | 160 | 480 | 280 |  |  |  | 30 | 100 | 50 | 900 | |

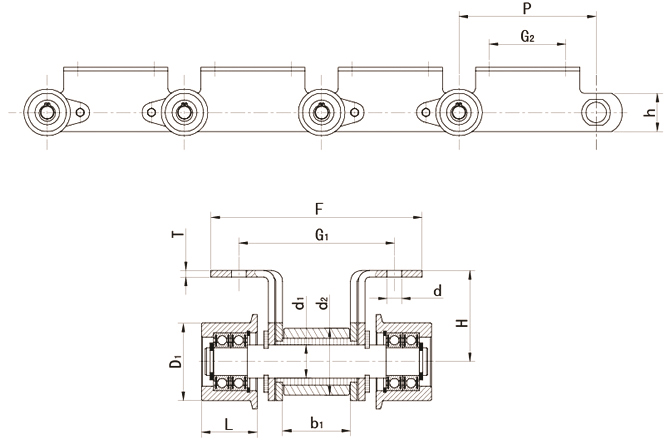

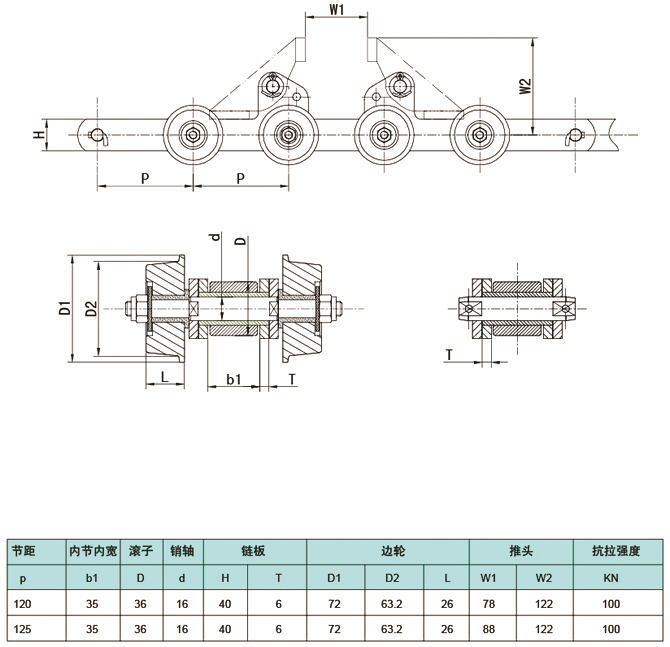

Automobile production line chain mainly refers to all kinds of conveying chains used in automobile manufacturing logistics conveying system According to customers' needs.

chains with various styles and different functions are provided for different production fields.

All kinds of conveying chains have the following characteristics:

1. Swing bar chain: the design of external roller and oil injection hole structure is adopted to realize stable operation of the chain and prolong its service life.

2. Drying room line chain: special design is adopted to meet the working condition of 250℃ high temperature and ensure the reliable operation of the production line.

3. Painting line chain: high-quality materials and precision manufacturing are selected to meet the use in specific environments.

4. Traveling machine chain: specially designed high-strength roller chain and eccentric chain with large pitch ensure efficient operation of different production lines.

5. Anti-skid chain: with anti-skid structure design, it can effectively prevent the car body from sliding down and ensure the safe operation of the production line.

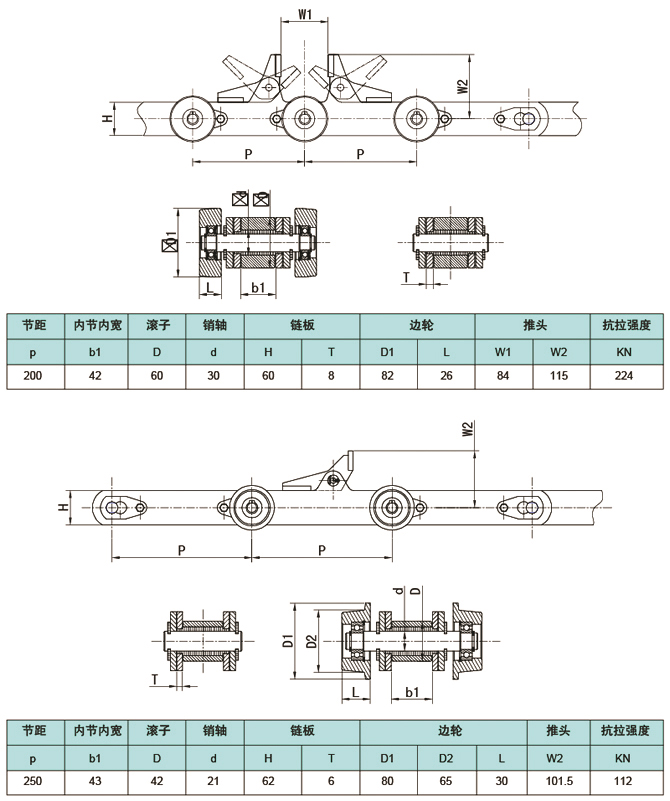

6. Pusher chain: Through optimized design, the products are widely used in painting, welding, drying, and other processes, so as to ensure the smooth running of the car carrying the car body on the track.

7. Rain line chain: made of high-quality stainless steel and precision. It can meet the needs of long-term operation in the water environment.

8. Chain of assembly line: According to the characteristics of the production line, the main products include all kinds of toothed conveyor chains and long pitch conveyor chains, with tensile strength above 45okN.