What are the different grades of chain?

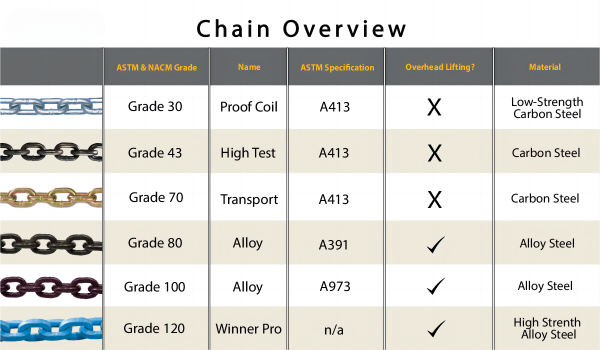

There are many different types of chains on the market and to find out what chain is best for your particular towing, lifting, rigging, or everyday application, it’s important to get a general idea of what is meant by the term chain grades. Chain grades are numerical levels that segment types of chains by their overall strength. There are six key chain grades ranging from chain grade 30 to chain grade 120. The higher the number, the stronger the chain. Furthermore, high-grade chains are typically harder, more resistant to abrasion, and contain a much higher strength-to-weight ratio compared to low-grade options. Selecting the right chain grade for your rigging application or chain slings is imperative as low-grade chains are subject to bending and breaking under extreme force. This can spell disaster and be extremely dangerous and even fatal in certain rigging scenarios. Knowing the grade of chain is imperative for the application due to the fact only ALLOY chain is approved for overhead lifting. Also, chain slings must be tagged with Working Load Limit (WLL), grade, length, name or logo of manufacturer and diameter. Serial number for traceability is also important.

How do you calculate chain grade?

A chain’s grade number (30, 43, 70, etc.) refers to its maximum tensile force in Newtons divided by a link’s cross-sectional area in millimeters. Or to put it more simply, a chain’s grade is its maximum stress in Newtons per millimeter squared. The mathematical equation would look like this:

Chain Grade = Newtons / millimeters2

By using this equation, we acknowledge that grade 30 chain can endure 300 Newtons per millimeter squared before bending or breaking. While this chain is perfect for your backyard swingset, it would be far too fragile and have much too low of a working weight limit for heavy-duty, towing, or overhead lifting applications.

Chains are mechanical devices made up of interconnected links designed to transmit force and motion. They come in various grades, each with specific characteristics and applications. The most common grades of chains include:

Grade 30:

Also known as proof coil chain, Grade 30 is a general-purpose, low-strength chain primarily used in applications requiring light to moderate loads. It is commonly used in towing, logging, agriculture, and general utility purposes.

Grade 43:Grade 43 chain, also called high-test chain, offers higher tensile strength than Grade 30. It is suitable for applications requiring a stronger chain, such as transportation tie-downs and marine anchor chains.

Chain Grade 50

Relatively uncommon as compared to other chains on this list, type 316 stainless steel chain grade 50 is the only stainless steel chain rated for overhead lifting applications and approved by OSHA when properly tagged. Depending on the width of the link, grade 50 carries a working load limit of 660 to 11,000 pounds.

Chain Grade 63

Chain grade 63 is an excellent choice for food processing applications or settings in which chemicals are used. Grade 63 boasts excellent resistance to heat, rust, chemicals, and saltwater and, if properly tagged, can be used in some overhead lifting applications. Depending on the width of the chain, grade 63 carries a working load limit of 2,800 to 9,000 pounds.

Grade 70:

Grade 70 chain is a high-strength, heat-treated carbon steel chain with a gold chromate finish. It is specifically designed for transportation tie-downs, load binding, and heavy-duty towing applications. The "G70" marking is usually visible on the links.

Grade 80:

This alloy steel chain is heat-treated for even higher strength and durability compared to Grade 70. Grade 80 chains are popular in overhead lifting applications and are known for their excellent resistance to wear and abrasion.

Grade 100:

Grade 100 chain is a premium-grade, alloy steel chain with the highest strength among the common grades. It provides superior performance in overhead lifting and slinging applications where safety and reliability are critical.

Chain Grade 120

Relatively new to the market, and still fairly rare among common suppliers, chain grade 120 is the strongest chain in the industry–about 50 percent stronger than grade 80 and about 20 percent

stronger than grade 100. Chain grade 120 is perhaps the most easily distinguishable of the chain grades, not only because of its distinctive blue color but because the links are rectangular rather than round ovals. Chain grade 120 is suitable for the most demanding of rigging applications and carries a working load limit of between 5,200 to 27,500 pounds depending on the width of the link.

Laclede Chain Manufacturing currently makes a traditional rounded link G120 and it will coat it green for visibility.

Stainless steel chains are corrosion-resistant and suitable for use in environments where exposure to moisture and chemicals is a concern. They come in various grades, such as 304 and 316 stainless steel, with Grade 316 offering the highest corrosion resistance.

Plastic Chains:Plastic chains are made from durable polymers and are used in applications where non-metallic, lightweight, and corrosion-resistant properties are required, such as in food processing and packaging industries.

It's important to choose the appropriate grade of chain based on the intended application and the required strength and corrosion resistance. Safety is paramount when using chains, especially in lifting and load-bearing applications, so always ensure that the selected chain meets or exceeds the required working load limits and safety standards.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com