What Is Chain Drive?

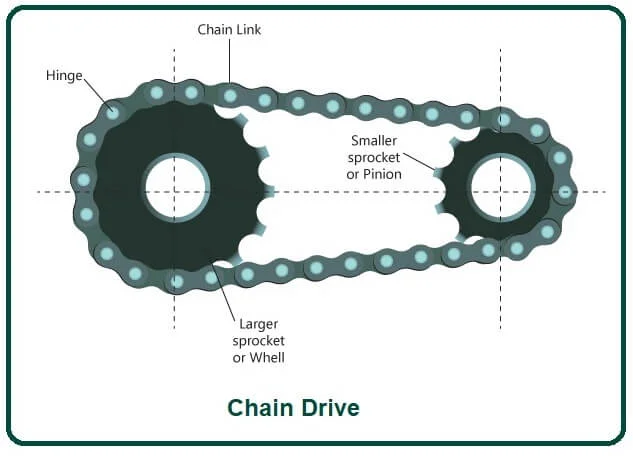

Chain drive is a way to transfer mechanical power from one place to another. Chain drives are widely used in vehicles such as bicycles and motorcycles to transfer power to the wheels. It is also used in different types of machines. Most often, power is communicated by a roller chain, known as a drive chain or transmission chain, that passes over a sprocket gear, with the gear teeth intersecting holes in the chain’s links.

The gear is rotated, and this pulls the chain, exerting mechanical force in the mechanism. The chain is made up of several rigid links that are held together by pin joints to provide the necessary flexibility to wrap the driving and driven wheels. Chains are mostly used to transfer speed and power from one shaft to another when the center distance between their shafts is small such as in bicycles, motorcycles, agricultural machinery, conveyors, rolling mills, road rollers, etc.

The chain can also be used for long center distances of up to 8 metros. Chains are used for velocities up to 25 m/s and power up to 110 kW. In some cases, higher power transmission is also possible. These wheels have special profile teeth and fit the corresponding recess in the chain link. Toothed wheels are known as sprocket wheels or simply sprockets.

Thus the sprocket and chain are constrained to move together without slipping and ensuring the correct velocity ratio. Chains are suitable for relatively long or short center distance drives and give a more compact drive than is possible with belts.

Some Features of Chain Drive:- The alignment of the shaft should be more precise than that of the belt. Center distance is not as important as gear drives. Proper lubrication must be provided for satisfactory service life. Their efficiency is compared to any other type of positive motivation.

Chain drives have greater versatility, adaptability, and reliability. They are an important component of lifting and moving machinery. Their cost is competitive due to automated production and extremely high rates of demand. Chains are low in cost, easy to install and maintain.

Basic characteristics of chain drives include a stable ratio, as no slippage or creep is involved, long life, and the ability to drive multiple shafts from a single power source.

Chain Drives for Transmission:

The Chain Drives are the most important drives for transmissions of electricity. It is a positive drive system as opposed to self-drive. The velocity ratio of the chain drive, that is, the ratio of the angular velocity of the driving sprocket wheel, remains constant without slip and without creep. In this case, the velocity ratio is as high as eight, which is quite high.

Completes assembly of the chains drive system. It consists of two toothed sprockets and a chain. Chain drives are very suitable for power transmission for short center-to-center distances and can be suitably used up to 2.5 meters but, however; The distance can be increased in most special applications. The single-chain can be used to drives multiple shafts to transfer power.

These chains have longer life as compared to belt drives, but the operation is not so smooth. The chain drive produces noise in operation due to impact when the chain roller contacts the sprocket tooth. There is variation in the speed of the chain from one tooth to the next.

This can cause vibration. The lubrication of the chain is done essentially to ensure smooth working, with a noiseless operation, and to ensure a long and trouble-free life of the chain. In this regard, the arrangement of the transmission chain drive system will essentially consist of an endless chain and two wheels called sprockets. Sprockets are toothed wheels, as shown, attached to an endless chain.

Endless chains of different sizes are formed depending on the distance from the center to the center of the circle. The most important applications of chain drive systems in power transmission are bicycles, motorcycles, scooters, machine tools, conveyors, etc.

Types of Chain Drives:

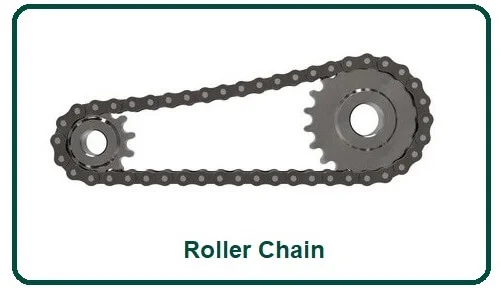

#1. Roller Chain

This types of chain are most commonly used for the transmission of mechanical power on many types of household, industrial and agricultural machinery, including conveyors, wire- and tube drawing machines, printing presses, cars, motorcycles, and bicycles. A roller chain consists of series of small cylindrical rollers held together by side links. It is driven by toothed wheels called sprockets. It is simple, reliable, and efficient for power transmission.

These chains are usually smaller in diameter than the height of the chain’s link plates. Link plate serves as guides when the chain engages the sprocket, Chain tracks or also serve as a guide to support the material on the way, as characteristic of conveyors and some bucket elevators. Roller chains are used for both drive & conveyor applications.

The chain most commonly used for drives is the single-strand standard chain roller chain. The power rating capabilities of these series cover a wide range of drive load requirements. Multiple-strand roller chains are used to provides increased power capacities without the need to increase the chain pitch or its linear speed.

#2. Silent Chain

Silent chains, also called inverted tooth chains, consist of a series of tooth link plates mounted on joint components in a way that allows free flexing between each pitch. Silent chains are made up of vertical rows of flat link plates, which have a gear-type shape designed to engage the sprocket teeth in the same way that a rack engages a gear in the picture. It is being displayed.

The links are held together by one or more pins at each chain joint, which also allows the chain to flex. A silent chain from differents manufacturers usually cannot be connected together. Standard silent chain is used in a wides variety of industrials drives where a compact, high speed, smooth, low noise drive is required.

High-performance silent chains are available in a wide range of sizes with pitches and widths and are used on very high-speed drives where exceptional smoothness and quietness are required. These series are commonly used in industrial equipment where ultimate smoothness is required.

#3. Leaf Chain

Leaf chains are designed for lifting rather than power transmission. The Tension is high, but the pace is slow. Normally the chains work intermittently. The main considerations in the design of leaf chains are tensile load, joint wear, and link plate and sheave wear.

Leaf chains are not forged with sprockets, as they are intended to run on mirrors, so there is no provision for them to the sprocket.

Leaf’s chains must often lift very large loads, & therefore require high yield strength, and do not stretch permanently when they lift large loads. Perhaps the most common use for a leaf chain is on lift trucks.

#4. Flat Top Chain

Flat-top chains are widely used on conveyors, which are basically used on special types of slate conveyors. Includes flat-top series of steel top plates with hinged-like barrels mounted on each side. Pins are inserted through the barrel to form a joint. These act as both beams and bearing.

The pins are maintained by a press fit or heading into the barrel of one top plate and are free to clear into the barrel of the next link. The connecting pin is usually either mounted or enlarged at one end to maintain the pin in a barrel of the top plate. Thus a continuous length of flat-top chains is formed. The flat-top chain is for conveying only.

#5. Engineering Steel Chain

The Engineering steel chains were first developed in the 1880s, designed for tough conveying applications. Most engineering steels chain are used in conveyors, bucket elevators, & tension linkages. Only a few are used in the drive. The main design considerations for these series are tensile load, multiple types of wear, lubrication, and environment.

Wear is the most important parameter when designing engineering steel chains. Joint wear, roller & bushing wear, & sidebar, and track wear are all major concerns for conveyor chains.

Advantages of Chain Drives:

There are many advantages offered by chain drives. Here are some written below:

· In chain drives, the tolerance between the shaft center distances is limited to the exact.

· Dimensions of given groups of gears. These precise specifications make it quiet. Effective for a variety of uses.

· Chain drive installation is fairly easy. It’s the best choice for those who don’t Want complicated installation techniques.

· Much easier than the possibility to redesign and configure chain drives for others.

· Chain drive performance is effective and better than other drives Shock loading conditions.

· Chain drives are effective for fluent speeds as the operating load is spread Numerous teeth. It is quite advantageous compared to other types of drives.

· Bearing loading is substantially reduced as these chain drives are not required Tension on the slack side, which is in the belt drive.

· The manufacturing and maintenance cost of chain drives is much lower than other drive systems.

· With chain drives, we can get maximum transmission efficiency which can be up to 98%.

· From this, we can get an optimum velocity ratio as there is no substitute slippery.

Disadvantages of Chain Drives:

· There is a possibility of velocity fluctuations when chain drive is used, and chains get stretched in harsh conditions.

· The major reason for these chains suffering from excessive vibration is the chordal effect.

· The cost associated with producing a chain drive is comparatively high compared to other drive options.

· It is quite important to mount it accurately and accurately when installing the chain drive.

· The maintenance required for chain drives is also high as one has to provide constant lubrication and adjustment of slack.

· Without proper lubrication, these chains are more prone to wear and tear.

Applications of Chain Drives:

The Chain drives are used in a variety of industrial applications, such as:

· A chain drive is a device widely used for the transmission of electricity where shafts are separated by a distance greater than that for which gears are practical.

· Rigging and moving heavy materials

· Hydraulic lift truck fork operation

· Overhead Hoist

· Operating Belt Conveyor

· Chain drives are used in many industries for many purposes, such as the transportation industry, agricultural machinery, material handling equipment, and building construction.

· Increase or decrease the driver’s output speed by changing the gear ratio between the driver and the driving sprocket.

Chain drives are mechanical systems that transmit power using a chain, which is a series of interconnected links. Chain drives offer a reliable and efficient means of power transmission in various applications due to their durability, load-carrying capacity, and ability to operate under harsh conditions. Here are some common applications of chain drives:

Automotive Industry: Chain drives are used in various automotive applications, such as timing chains that synchronize the movement of the engine's camshaft and crankshaft. They are also found in transfer cases, where they distribute power between the front and rear wheels in four-wheel-drive vehicles.

Industrial Machinery: Chain drives are widely used in industrial machinery for conveying materials, such as in conveyor systems, elevators, and escalators. They are also employed in machines like printing presses, textile machinery, and packaging equipment.

Agricultural Machinery: Chain drives are utilized in various agricultural equipment, including tractors, combines, and other machinery used for planting, harvesting, and processing crops.

Motorcycles and Bicycles: Chain drives are commonly used in motorcycles and bicycles to transfer power from the engine or rider's legs to the wheels. They provide an efficient and lightweight means of power transmission.

Construction Equipment: Many construction machines, such as cranes, bulldozers, and excavators, use chain drives to transfer power from the engine to the equipment's moving parts.

Mining Equipment: Chain drives are employed in heavy mining machinery for tasks like moving materials, drilling, and transporting ores and minerals.

Material Handling Equipment: Chain drives are utilized in material handling equipment like forklifts, palletizers, and automated storage and retrieval systems to move and position materials within warehouses and factories.

Marine Industry: Chain drives are found in marine applications, including ship propulsion systems, anchor windlasses, and winches used for various tasks onboard ships and boats.

Textile Industry: Chain drives are used in textile machinery for tasks like spinning, weaving, and knitting, where precise and synchronized motion is required.

Power Transmission: In power transmission applications, chain drives are used to transmit power from one rotating shaft to another. They are commonly found in industrial machinery, manufacturing equipment, and processing plants.

Oil and Gas Industry: Chain drives are employed in drilling equipment and pump systems used in the oil and gas industry for extracting and transporting resources.

Food Processing: In the food industry, chain drives are used in processing and packaging equipment, conveying systems, and machines for tasks such as baking and bottling.

Printing and Paper Industry: Chain drives are utilized in printing presses and paper machines to synchronize the movement of rollers, cylinders, and other components involved in the printing and paper manufacturing process.

Power Generation: Chain drives are used in power generation equipment, such as turbines and generators, to convert rotational motion into electrical energy.

Renewable Energy: In applications like wind turbines, chain drives are used to transfer power from the wind turbine's rotor to the generator, converting wind energy into electricity.

These applications demonstrate the versatility and utility of chain drives across various industries, making them an essential component of modern machinery and equipment.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com