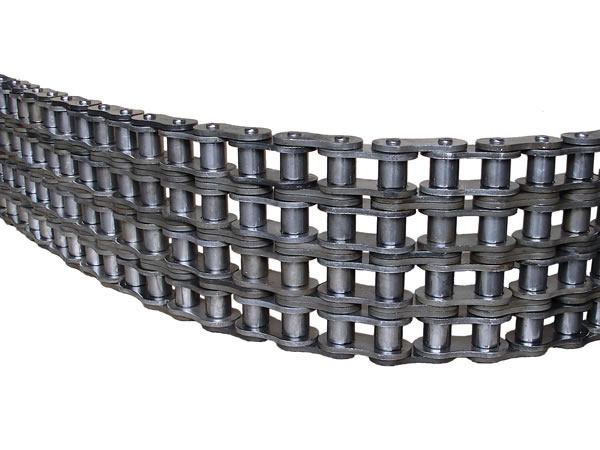

There are many types of chains, which can be divided into: transmission chains, transport chains, decorative chains, cable-tightening chains, special chains, etc. according to their use. According to the structure of the chain: it can be divided into roller chain, sleeve chain, plate chain, nylon roller chain, scraper chain, sleeve chain and so on.

Most of the chains are composed of chain plates, chain pins, shaft sleeves and other components. Other types of chains just make different changes to the chain plates according to different needs. Some are equipped with scrapers on the chain plates, some are equipped with guide bearings on the chain plates, and some are equipped with rollers on the chain plates. These are all modifications to be applied in different application places.

For ordinary chains, the smooth parts are mainly the sprocket and the rollers of the chain, the chain shaft and the bushing. Due to the different structure of the chain, the smooth part of the chain may also be altered. However, in most chains, the smooth parts are mainly the sprocket and the rollers of the chain, the chain shaft and the bushing.

Since the matching clearance between the shaft of the chain and the shaft sleeve is small, it is difficult to be smooth. Regarding special chains: such as chains equipped with bearings, rollers and other friction pairs, the smooth parts of these friction pairs should also be considered.

The main failure mode of the chain:

1. The pin is broken;

2. Pitch growth;

3. The tooth of the sprocket is broken;

4. Chain card bite

Smooth oil should be selected as much as possible. For special chains and special conditions, smooth grease and dry film smoothing agent can be selected. The request for smoothing agent when the chain is running should be met to the greatest extent, and the requirements of equipment and consumption should be separated, and suitable and economical smoothing agent should be selected.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com