Industrial Roller Chain Wear & Elongation

Roller chain wear can be categorized into three main types:

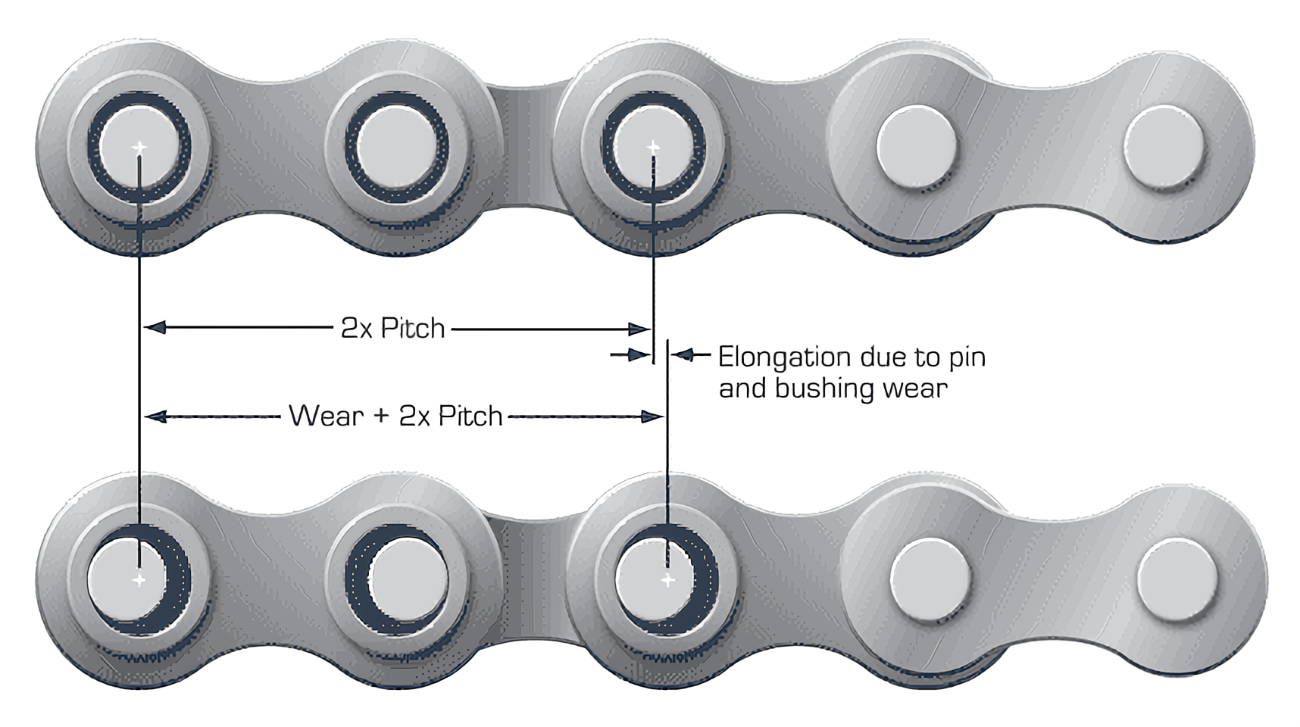

Elongation: Elongation refers to the stretching or lengthening of the chain over time. It occurs when the chain's pins and bushings wear down, causing the chain to become longer. Elongation leads to increased pitch between the rollers, which affects the accuracy of speed ratios and can result in poor performance of the machinery.

Side Plate Wear: Side plate wear happens when the contact between the chain and sprocket causes friction and material removal on the outer surfaces of the chain's side plates. This type of wear can lead to a decrease in chain width and affect the engagement with the sprocket teeth, resulting in inefficient power transmission and potential chain slipping.

Roller Wear: Roller wear occurs when the rollers experience friction against the sprocket teeth. It can lead to surface degradation and material loss from the rollers, affecting their smooth rotation and causing increased friction and wear on other chain components.

Possible Solutions for Roller Chain Wear:

To mitigate roller chain wear and elongation, the following measures can be taken:

Proper Lubrication: Regular lubrication is crucial to reduce friction and wear. Lubricants create a protective film between the chain components, minimizing metal-to-metal contact and reducing wear. Lubrication also helps to dissipate heat generated during operation.

Correct Tension: Maintaining proper chain tension is essential to prevent excessive wear. Chains that are too loose can lead to slippage and accelerated wear, while chains that are too tight increase stress and friction. Regular tension checks and adjustments are necessary.

Alignment and Sprocket Inspection: Proper alignment between the drive and driven shafts, as well as regular inspection of sprocket teeth, are important. Misalignment and worn or damaged sprockets can cause uneven wear and accelerated chain deterioration.

Regular Maintenance and Inspection: Implementing a preventive maintenance program that includes regular cleaning, lubrication, and inspection of the chain can help identify and address wear issues before they cause significant problems. Replacing worn chains and sprockets in a timely manner is important to prevent further damage.

Selecting the Right Chain: Choosing a roller chain that is suitable for the application's load, speed, and environmental conditions is critical. Different chain types, materials, and coatings may be required to enhance wear resistance and durability.

By understanding the causes of roller chain wear and implementing appropriate maintenance practices, it is possible to extend the service life of roller chains, improve operational efficiency, and minimize costly downtime.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com