1. Elongation Chain Half-section Repair

Generally, chain transmission has tension device, but some agricultural machinery does not have this structure. Because of the chain elongation, the transmission will run and knock, and it will not work properly. If the chain wear does not exceed the limit, then a group of chains can be removed and adjusted to the appropriate tightness, but this will happen in practice; if a group of chains is not too long, a group of chains is too short. When repairing, half of the chains can be modified and removed.

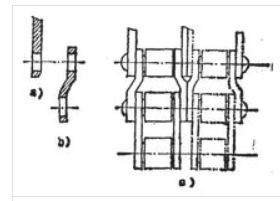

When the single-row sleeve roller chain is refitted, two cylindrical pins are flushed down, one roller, sleeve and two inner chains are removed, two outer chains are pulled into the shape of figure b, and then arcs are filed at the corresponding points of two adjacent outer chains (figure a) to avoid friction after assembly. For ease of installation, the rollers and sleeves at the refitting site can be appropriately filed a little shorter, and then assembled according to figure C.

Schematic diagram for repairing half-section of chain

Double sleeve roller chains can also be repaired by similar modification methods.

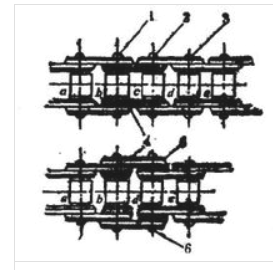

Another modification is to lengthen the pin shaft when the structure permits (as shown below). Firstly, the chain pins 1, 2 and 3 are removed to separate the chain. Then the two inner chains connecting the rollers B and C are removed and made into four circular pads. Two are left in the original place of the rollers b, and the other two are placed in the outer position of the rollers D. Remove the roller C and rivet it with two long pins.

Schematic diagram for repairing half-section of chain

Figure: 1, 2, 3 pins; 4 inner chains; 5 outer chains; 6 - long pins

2. Repair of worn chain

The pitch of the chain increases after wear, which is mainly due to the wear of the simple edges of the pin and sleeve.

According to the equipment condition, decomposition or non-decomposition repair can be adopted.

Decomposition repair

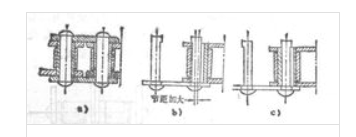

According to the repair principle of adjusting transposition method, the pins and sleeves with unilateral wear are turned to 180 degrees so that the normal pitch will be restored (fig. C below). For this reason, the chain with excessive wear and tear is completely decomposed, the damaged parts are eliminated, and the parts that can be used are reassembled according to the above methods. About 80% of the parts can continue to be used.

Wear and Adjustment of Sleeve Roller Chain

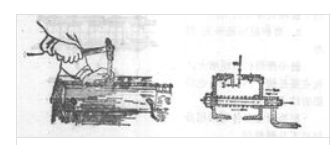

Simple special equipment should be used when sleeve roller chain is decomposed. The length of the two channel steels is 500 mm. The tightening screw head is welded on one side of the channel steel. The spacing of the channel steel can be adjusted by shaking the threaded handle according to the different pitches of the chain, so that the chain is supported on the channel steel. The spring force in the screw always pushes the channel steel to ensure the opening of the channel steel.

Decomposition Equipment of Sleeve Roller Chain

After the chain is loaded into the equipment, the small axle of the fork arm is hit out by the punch in turn, and then the inner chain and sleeve are laid by the punch die.

After the chain is decomposed, it is carefully cleaned and identified, and parts can be selected for assembly. When assembling, the pin shaft is clamped by a vise, and the chain is twisted 180 degrees. The sleeve installed in the inner chain is also twisted 180 degrees, so that the wear surface of the sleeve is opposite on the inner side. In order to avoid the loose fit between the inner chain and sleeve, the punch is used to tighten the fit, and the pin shaft is riveted with the outer chain.

Non-decomposition repair

This is a relatively simple repair method, it does not need to decompose the chain, but to shorten the outer chain pitch, so that the whole chain pitch back to normal state.

When repairing, the chain is placed on the fixture, then the middle part of the outer chain is heated by high frequency electric current to reach the plastic state, and then the extrusion and upsetting of the outer chain is restored to the required pitch. In order to ensure the same processing pitch, a locator is placed between the rollers.

The repaired hinge part of the chain chain joint can rotate freely by hand and the roller can rotate freely in the sleeve. Then it is installed on the test bench and tested for 20 minutes at 350-400 rpm to check the operation and eliminate the problems found. The repaired chains should be immersed in waste oil at 80-90 C for 15-20 minutes, so that the internal friction surface of the chains can be well lubricated. Low temperature, short time oil is not

Easy to infiltrate into, if the high-frequency oscillator is switched to 1000-2000 times per minute when infiltrating, the infiltration effect will be better, and the time can be shortened to only 2-3 minutes. The chain after oil immersion should be hung up, dripped clean oil and then used or preserved.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com