Measures to reduce transmission error of machine tool transmission chain by roller chain

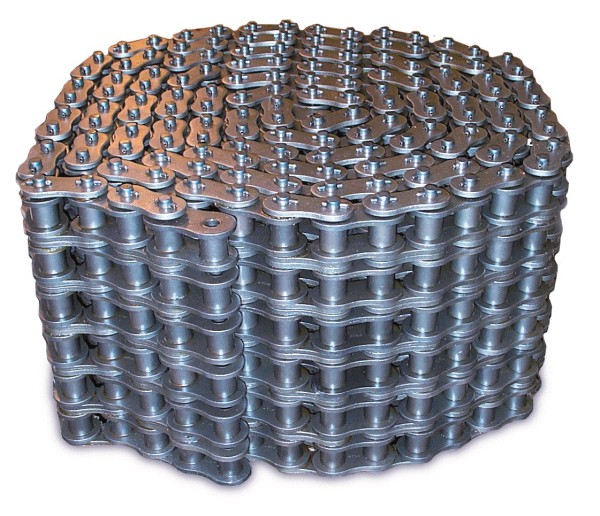

Roller chain - summarize several measures to reduce the error of the machine tool transmission chain, and further improve the machining accuracy and work efficiency.

1. Try to shorten the transmission chain as much as possible, such as the transmission system of a mass production thread grinding machine shown in the figure below. The machine tool uses interchangeable female screw and the processed workpiece are connected in series on the same axis. The female screw pitch is equal to the workpiece pitch, and the transmission chain Z is short, which can achieve relatively high transmission accuracy.

2. Reduce geometric eccentricity during the assembly of various transmission mechanical components and improve assembly accuracy.

3. Improve the manufacturing accuracy of the end components of the transmission chain. In general speed reduction transmission chains, the error of the end components has a significant impact on Z. Therefore, the accuracy of the end components such as the indexing worm gear of hobbing machines and the female screw of thread processing machines should be Z high.

4. Allocate the transmission ratio to each transmission pair in the transmission chain according to the principle of increasing the reduction ratio. The larger the reduction ratio of the transmission pair at the end of the transmission chain, the smaller the impact of errors on the other transmission components of the transmission chain. Therefore, the number of teeth of the indexing worm gear should be larger, and the pitch of the female lead screw should also be larger, which will make use of the transmission chain error.

5. Using a calibration device, the essence of the calibration device is to artificially add an error in the original transmission chain, which is equal in size to the error of the transmission chain itself but opposite in direction, thus causing them to cancel each other out.

For example, high-precision thread machining machines often use Cao Yong's mechanical calibration mechanism, as shown in the following figure. Based on the measurement of the lead error of workpiece 1 being processed, a calibration curve 7 is designed on the calibration ruler 5. The calibration ruler 5 is fixed on the machine tool body, and when processing threads, the machine tool mother screw moves the nut 2 and other fixed tool holders and levers 4. At the same time, the calibration error curve 7 on the calibration ruler 5 passes through the contact 6, and the lever 4 causes the nut 2 to generate an additional transmission, thereby causing the tool holder to obtain an additional displacement to compensate for the transmission error.

The use of mechanical correction devices can only correct the static transmission error of the machine tool. If the dynamic transmission error of the machine tool needs to be corrected, a computer-controlled transmission error compensation device needs to be used.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com