Introduce the use and operation of stainless steel chains

Short pitch roller chain for transmission, double pitch roller chain for transmission, sleeve chain for transmission, bent plate roller chain for heavy load transmission, toothed chain for transmission, stepless speed change chain, long pitch walk chain, short pitch roller walk chain, double pitch roller walk chain, double speed walk chain, plate chain, etc. Other products are as follows:

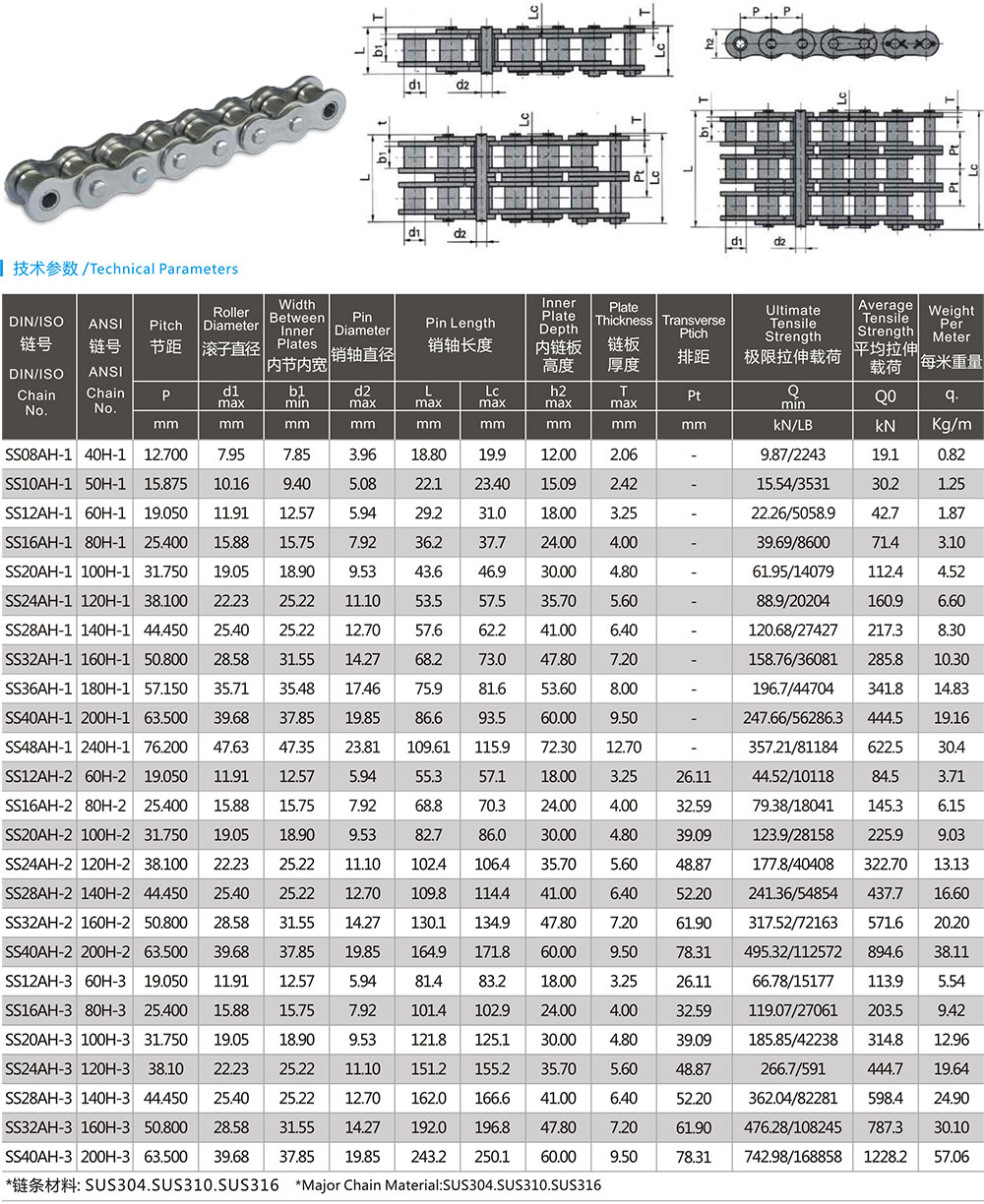

Stainless steel chain: The part information is stainless steel. This type of chain is suitable for use in the food industry and places susceptible to chemical and pharmaceutical corrosion. It can also be used in high-temperature places.

Nickel plated chain, galvanized chain, chrome plated chain: All chains made of carbon steel materials can be disposed of externally. The surface of the parts is treated with nickel plating, galvanizing, or chrome plating. It can be suitable for outdoor use in places such as rainwater corrosion, but cannot avoid concentrated chemical liquid corrosion.

Self smoothing: Some parts are made of sintered metal soaked in smooth oil. This type of chain has excellent wear resistance, corrosion resistance, maintenance free, and long service life. It is commonly used in places with high stress, wear resistance requirements, and cannot be frequently maintained, such as active production lines in the food industry, high-end bicycles and racing cars, and low maintenance of high-precision machinery.

O-ring chain: there is an O-ring seal between the chain plates in the roller chain list to prevent dust from entering and grease from flowing out. The chain undergoes severe pre smoothing. Due to its strong components and reliable smoothness, the chain can be used in open transmissions such as motorcycles.

Rubber chain: This type of chain is equipped with a U-shaped attachment plate on the outer link of the A and B series chains. Sticking rubber (such as natural rubber NR, silicone rubber SI, etc.) on the attachment plate can add wear resistance, reduce noise, and add shock resistance. Used for delivery.

Sharp toothed chain: This type of chain is commonly used in the wood industry, such as feeding and output of wood, cutting, conveyor delivery, etc.

Agricultural machinery chain: agricultural machinery chain is used for field work machinery, such as walking extension machine, threshing machine, combine harvester, etc. This type of chain requires low cost but can withstand impact and wear. In addition, the chain should be coated with grease or actively smooth.

High strength chain: it is a special roller chain. After improving the shape of the chain plate, thickening the chain plate, fine punching the chain plate hole, and strengthening the heat treatment of the pin shaft, the tensile strength can be improved by 15~30%, and it has excellent impact function and fatigue function.

Side bending chain: This type of chain has a large gap between buttons and chain plates, making it highly sensitive and suitable for bending transmission and delivery.

Active escalator chain: used for active escalators, active pedestrian walkways. Because the active escalator task takes a long time, requires high safety requirements, and operates smoothly. Therefore, it is required that this step chain must reach the minimum limit tensile load of the rule. The total length of two paired chains is biased, and the step distance is biased.

Motorcycle chain: defined by the use of the chain. It can be divided into two types: roller chain and sleeve chain from the structure of the chain. It can be divided into two types from the part used on the motorcycle. It can be used inside the engine and outside the engine. Most of the chains used inside the engine are sleeve chain structures. The chains used outside the engine are transmission chains used to drive the rear wheels. Most of them use roller chain. This type of chain should pay special attention to its fatigue function.

Agricultural holding and escorting chain: applicable to walking wheat, rice harvester, fixed flexible rice and wheat threshing machine, and semi feeding combine harvester.

Hollow pin chain: used for delivery. Single pitch, double pitch, and long pitch are all available. Accessories or crossbars can be inserted into any link of the chain without the need to disassemble the chain.

Timing chain: used for transmission between the engine crankshaft and camshaft. Because there are strict requirements and rules for the travel of the engine piston and the exhaust time, this type of chain is called a timing chain. Both roller chain and toothed chain can be used as timing chain. The timing chain is primarily used for the transmission of starting engines (diesel or gasoline engines) in automobiles, motorcycles, and steamships. In order to reduce the weight of the initiator, the gap between the chain and the initiator device is very small, and some even do not have tension installation. Therefore, in addition to high precision requirements, the wear resistance function of the timing chain is also quite high.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com