Importance of industrial Roller chain & Conveyor Chain

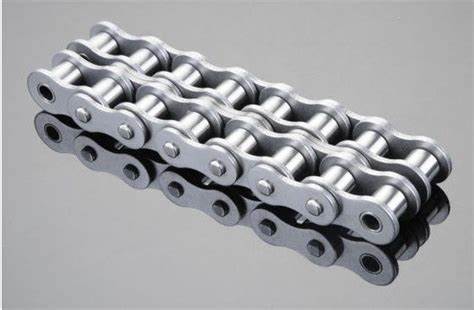

In the process of industrial production, industrial chain is a very important part, and it is an irreplaceable transmission tool in the production process. After years of development and precipitation, today's industrial chain has been quite rich in varieties.

Now, roller chains are widely used, such as sleeve chains and long pitch chains. However, for specific purposes, the current industrial chains are mostly used for transmission and transportation.

Importance of industrial chain to industrial production

1. Nowadays, the manufacturing technology of these chains by major manufacturers has basically become more and more mature, and the quality and reliability of industrial chains are getting better and better. For example, multi tooth chains are also quite safe and reliable in the transmission process. Compared with the traditional old belt transmission, industrial chains are more precise and transmission efficiency is higher.

2. The industrial chain can still bring perfect use effect to users in a very complex and harsh use environment, which is also the embodiment of the strong applicability of the industrial chain. Today's chain products are basically manufactured by machinery and equipment, and adopt more advanced heat treatment process and stamping forming. They are also different in quality. They are widely used in transportation industry, light textile industry, metallurgy and high-precision instrument industry.

3. There has also been a great breakthrough in the selection of materials and types, including corrosion-resistant stainless steel chain, powder metallurgy chain, etc. users can select the appropriate chain according to the specific use environment to achieve ideal use effect, so as to promote the production efficiency of various industries.

Conveyor chains, roller chains and plate chains are used in dynamic applications, so how the chains move and how the components contact each other is very important. In other words, the wear mode of the chain - fatigue strength - is the key factor.

It is relatively easy to produce a chain to a specific breaking strength, but not to achieve high fatigue strength. In order to sort wheat from chaff, buyers need to find manufacturers who can do it at the same time, which requires some questions about the manufacturing method of the chain.

How do you ensure the consistency of raw materials?

Inconsistent raw materials will prevent stamping and stamping tools from maintaining accurate tolerances and will not harden at the same rate during heat treatment. Problems will occur during assembly, and the weakest part of the chain will fail first in use.

How do you ensure consistent tool and component tolerances?

Even if the raw materials have the same quality, if the stamping tool does not meet the good standard, it will produce inconsistent and inaccurate parts, and the wear speed will be much faster. Components produced with good tools and processed to strict tolerances will have the largest bearing area and the closest fit during assembly, ensuring minimum wear and long service life.

How do you optimize the heat treatment process of different products?

Ensure that the heat treatment is optimized for each product to form the correct hardness depth so that the chain can withstand the impact load. If a component becomes completely hardened and brittle, it will be prone to fracture and premature failure.

Do you have automated assembly and welding lines?

Careful control of the chain assembly ensures its consistency and reliability during its service life. Having an automated assembly line, including for parts that need to be welded, the resulting process is not only efficient, but also can depend on maintaining the best performance of the chain.

Will you stretch your chain in advance?

In the production process, each component is produced according to a certain tolerance. These components are then assembled under no load, so a pre stretching procedure is required before the chain is put into use. This involves placing the chain under a certain percentage of the load it bears during operation to eliminate any tolerances in the components and bed parts, put them in the best position and prepare them for production application.

Of course, there are subtle differences in the specific characteristics of the control chain, but these are the basis for the production of high-quality industrial chains with high fatigue strength and long wear life. If the chain manufacturer cannot easily answer the above questions for any reason, you may not be able to obtain the required high-quality industrial chain with low total cost of ownership.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com