How to choose the lubrication of roller chains?

The chain of mechanical equipment in various industries is one of the mechanical transmission components. Due to its many excellent characteristics such as the accurate transmission of power, stable transmission, constant speed ratio, strong adaptability, freedom from size impact, and convenient maintenance, it is widely used in various mechanical equipment. Especially in today's highly automated production equipment. Roller chains have become one of the main transmission components of mechanical transmission.

Basic Requirements for Lubricants in Chain Drives

1. Type of chain

There are many types of chains, which can be divided into transmission chains, conveyor chains, engineering chains, lifting chains, agricultural machinery chains, and special chains according to their uses. According to the structure of the chain, it can be divided into roller chains, sleeve chains, plate chains, nylon roller chains, scraper chains, collar chains, etc.

2. Chain structure

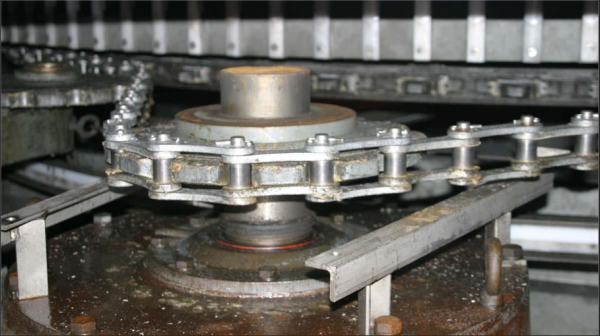

Most chains are composed of chain plates, pin shafts, sleeves, rollers, and other components. Other types of chains only have different modifications made to the chain plates according to different needs. Some have scraper plates installed on the chain plates, some have guide bearings installed on the chain plates, and some have rollers installed on the chain plates. These are modifications made for different applications.

3. Main lubricating parts of the chain

For general chains, the main lubrication areas are the sprocket and chain rollers, pin shafts, rollers, and sleeves. Due to the different structures of the chain, the lubrication position of the chain may also change. However, in most chains, the main lubrication areas are the rollers, pins, and rollers of sprockets and chains.

Due to the small fit clearance between the pin and roller of the chain, lubrication is relatively difficult. For special chains, such as those equipped with bearings, rollers, and other friction pairs, the lubrication position of these friction pairs should also be considered.

4. Main failure modes of chain

A: Pin shaft fracture, B: Pitch increase, C: Sprocket tooth fracture, D: Chain seizure

GIDI CHAIN LIMITED supplies lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com