How Many Types of Conveyor Chains are There?

There are several types of conveyor chains, each designed for specific applications and industries. The most common types include:

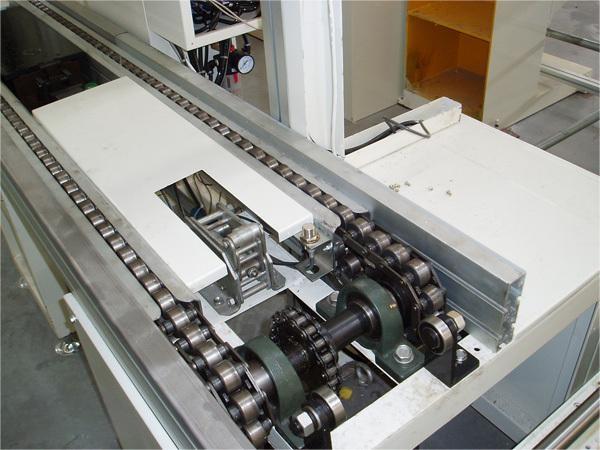

1. Roller Conveyor Chain

Overview: The most widely used conveyor chain, featuring rollers to reduce friction.

Applications: Common in material handling, logistics, and heavy-duty applications like automotive manufacturing.

Variants:

Straight sidebar: Used in heavy-duty applications.

Offset sidebar: Suited for lighter loads and smoother operation.

2. Silent Chain

Overview: Characterized by interlocking toothed plates, providing a quiet and smooth operation.

Applications: Used in industries requiring low noise, such as packaging, food processing, and automotive.

3. Double Pitch Chain

Overview: Has twice the pitch length of standard roller chains, making it ideal for longer conveyor systems with lighter loads.

Applications: Common in agricultural equipment, light conveyors, and packaging systems.

4. Leaf Chain

Overview: Consists of stacked plates and is primarily used for lifting rather than conveying.

Applications: Often found in forklift trucks, cranes, and hoists.

5. Plastic Conveyor Chain

Overview: Made from durable plastic materials, which offer corrosion resistance and are lightweight.

Applications: Used in food processing, pharmaceutical industries, and environments where corrosion is a concern.

6. Steel Pintle Chain

Overview: Designed with open barrel construction, allowing debris to escape easily.

Applications: Ideal for agricultural, sewage treatment, and conveying bulk materials.

7. Attachment Chain

Overview: Equipped with attachments or fixtures that allow for customized applications, such as moving specific products or components.

Applications: Used in industries like packaging, automotive, and material handling.

8. Specialty Conveyor Chains

Overview: Includes custom-designed chains for specific applications, such as chains with rubber tops for gripping or accumulation chains for controlled product movement.

Applications: Tailored for unique requirements in various industries, such as electronics, bottling, or glass manufacturing.

Each type of conveyor chain is selected based on the specific needs of the application, considering factors like load, speed, environment, and product being conveyed.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com