Automotive Engine Chains: Applications, Construction, and Trends

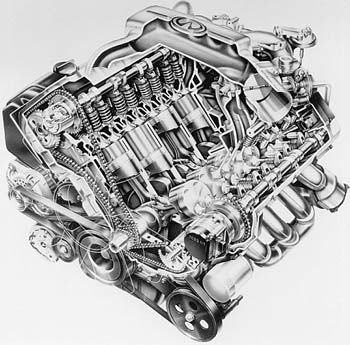

Automotive engine chains play crucial roles in various applications, including driving camshafts, counterbalance shafts, and oil pumps. While some manufacturers use cog belts instead of chains, the use of chains in this context remains prevalent. These chains transmit crankshaft rotation to the camshaft in overhead cam (OHC) engines at a 2:1 ratio, as well as driving counterbalance shafts and oil pumps, all within the engine and not visible from the outside.

Operating within a temperature range of −30°C to 130°C, these chains rotate at speeds ranging from 600 to 7,000 rpm. Counterbalance drive sprockets, in particular, reach speeds of 1,200 to 14,000 rpm (equivalent to 1,800 m/min), twice that of engine drive chains. While motorcycles also utilize camshaft drives, this discussion focuses on automobiles and roller chains, typically provided by Japanese or European manufacturers. In the United States, Silent Chains were once commonly used for camshaft drives, but roller chains are gaining popularity.

Construction and Features:

Automotive engine chains are typically single strand with a pitch of 9.525 mm or 8.0 mm. In high-load engines or diesel engines, double strand chains may be employed. Wear between pins and bushings is a primary concern due to the high speeds involved. To address this, the pin surface is usually hardened to Hmv 1,600 or more.

Sprockets:

Sprockets for automotive engines come in either ANSI- or BS-type tooth shapes, with the BS-type currently being more prevalent. Mass-produced from sintered metal, these sprockets are essential components of the engine's transmission system.

Selection and Handling:

To enhance performance and reduce issues like chain elongation, vibration, and noise, these chains are used in conjunction with chain guides, levers, and tensioners. Selection criteria typically include factors such as transmission torque, small-sprocket speed, and overall layout. In mid- to high-speed transmissions, vibration and lubrication are also important considerations. Forced lubrication is necessary for these chains.

Technical Trends:

Manufacturers are actively addressing various challenges and focusing on the following key issues:

Weight and Size Reduction: Efforts to make chains lighter and smaller to improve overall engine efficiency.

Transmission System Reliability: Improving the reliability of the entire transmission system, including sprockets, guides, levers, and tensioners.

Noise Reduction: Minimizing noise not only from the chain but also throughout the entire drive system for a smoother and quieter operation.

As technology advances, automotive engine chains continue to evolve to meet the demands of modern engines, ensuring optimal performance and efficiency in automobiles.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com