Chain Supporting Device for Preventing Chain Detachment

The present device discloses a chain support device for preventing chain detachment, which includes a bottom plate installed on a fixed beam, wherein the bottom plate is equipped with a lower nylon guide strip, and the bottom plate is also covered with a protective cover. The protective cover covers the top and two sides of the bottom plate, and there are openings for the chain to pass through at the front and rear ends of the protective cover. The top of the protective cover is connected downwards with an upper nylon guide strip, The upper nylon guide strip and the lower nylon guide strip correspond up and down, with empty slots reserved for chain transmission. The side of the protective cover extends horizontally to form a fixed side plate, which is connected to the bottom plate. The anti detachment chain supporting device of the present device can prevent the chain from jumping up and down during the chain transmission process, prevent the chain from falling off from the side, reduce noise and wear during the chain transmission process, and make the equipment operate more safely and stably.

1. A chain support device for preventing chain detachment, characterized in that it includes a bottom plate (1) installed on a fixed beam, wherein the bottom plate (1) is equipped with a lower nylon guide strip (2), and the bottom plate (1) is also covered with a protective cover (4), which covers the top and two sides of the bottom plate (1), and the protective cover (4) is provided with openings for the chain to pass through at the front and rear ends, The top of the protective cover (4) is connected downwards with an upper nylon guide strip (3), and the upper nylon guide strip (3) and the lower nylon guide strip (2) correspond up and down with empty slots (5) for chain transmission. The side of the protective cover (4) extends horizontally to form a fixed side plate (6), which is connected to the bottom plate (1).

2. A chain support device for preventing chain detachment according to claim 1, characterized in that both the upper and lower nylon guide bars are elongated, and the protective cover is vertically connected downwards with two parallel upper nylon guide bars, while the bottom plate is vertically connected upwards with two parallel lower nylon guide bars, forming a chain support structure at both ends of the chain.

3. A chain support device for preventing chain detachment according to claim 1, characterized in that the front and rear ends of the upper nylon guide strip are equipped with arc-shaped chamfers (7), and the front and rear ends of the lower nylon guide strip are also equipped with arc-shaped chamfers (7). The arc-shaped chamfers at the ends of the upper nylon guide strip and the lower nylon guide strip form a trumpet shaped opening shape with an empty groove at the end.

4. A chain support device for preventing chain detachment according to claim 1, characterized in that the top of the upper nylon guide strip and the protective cover are fixed by screws (8), and the screws are evenly distributed with three.

5. A chain support device for preventing chain detachment according to claim 1, characterized in that the bottom of the lower nylon guide strip and the anti base plate are fixed by screws (8), with three evenly distributed screws.

6. A chain support device for preventing chain detachment according to claim 1, characterized in that the fixed side plate (6) and the bottom plate (1) are fixed by bolts (9).

Technical field

[0001] The present divice relates to a chain transmission structure in mechanical devices, in particular to a chain support device for preventing chain detachment.

Background technology

In the lifting device of mechanical parking equipment, when the span of the chain is too long, a supporting chain is usually added in the middle of the long chain to prevent chain shaking. Generally, a nylon pad is added to a base to achieve this. However, general drag chain devices have drawbacks. Due to the length of the chain being too long, not only will it bounce up and down to produce noise during operation, but it will also detach from the nylon block guide groove of the supporting chain, causing safety issues..

Summary of the device

[0003] The present device aims to overcome the shortcomings of ordinary drag chain devices that fix chains not securely and are easy to jump out, and provides a safe and stable anti detachment chain support device.

[0004] In order to achieve the above purpose, the present invention adopts the following technical solution:

The present device relates to a chain support device for preventing chain detachment, which includes a bottom plate installed on a fixed beam, wherein the bottom plate is equipped with a lower nylon guide strip, and the bottom plate is also covered with a protective cover. The protective cover covers the top and two sides of the bottom plate, and there are openings for the chain to pass through at the front and rear ends of the protective cover. The top of the protective cover is connected downwards with an upper nylon guide strip, The upper nylon guide strip and the lower nylon guide strip correspond up and down, with empty slots reserved for chain transmission. The side of the protective cover extends horizontally to form a fixed side plate, which is connected to the bottom plate.

[0005] Compared to ordinary chain support devices that only have chain support function, the present device has the following significant effects:

1. We use two layers of nylon guide strips, one on top and the other on the bottom, with a gap left in the middle to clamp the chain to prevent it from jumping up and down, causing safety hazards.

[0006] 2. A protective cover has been installed above, which protects the top and two sides, preventing the chain from jumping out from the side. If there is a protective cover, the chain will not fall off, causing safety issues for the equipment.

[0007] 3. The guide bar adopts nylon guide bars, which can effectively reduce the noise generated in the transmission and reduce the friction loss on the chain.

[0008] As a preferred option, both the upper and lower nylon guide bars are elongated. The protective cover is vertically connected downwards to two parallel upper nylon guide bars, and the bottom plate is vertically connected upwards to two parallel lower nylon guide bars, forming a chain supporting structure at both ends of the chain. The ball of the chain drives the chain by passing through the gap between the upper and lower nylon guide bars. The two end support chain structure reduces the contact area between the chain and the nylon guide strip, reduces friction loss, reduces noise, and makes the chain transmission smoother while maintaining the support chain function.

[0009] As a preferred option, the front and rear ends of the upper nylon guide strip are equipped with arc-shaped chamfers, while the front and rear ends of the lower nylon guide strip are also equipped with arc-shaped chamfers. The arc-shaped chamfers at the ends of the upper nylon guide strip and the lower nylon guide strip form a trumpet shaped opening shape with an empty groove at the end. The trumpet shaped opening shape is beneficial for initial installation, facilitating the introduction of the chain into the empty slot, while avoiding sharp end wear on the chain's balls.

[0010] As a preferred option, the top of the upper nylon guide strip is fixed with screws between the protective cover, and the screws are evenly distributed with three.

[0011] As a preferred option, the bottom of the lower nylon guide strip is fixed with screws between the anti base plate, and the screws are evenly distributed with three.

[0012] As a preferred option, the fixed side plate and bottom plate are fixed by bolts.

[0013] The present device has the following beneficial effects: the anti detachment chain supporting device can prevent the chain from jumping up and down during the chain transmission process, prevent the chain from falling off from the side, reduce noise and wear during the chain transmission process, and make the equipment operate more safely and stably.

Illustrated Figures

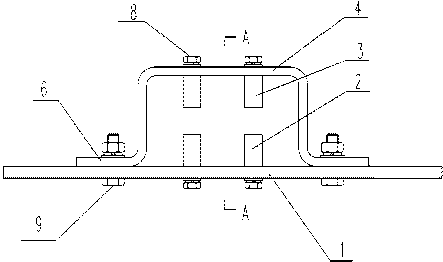

[0014] Figure 1 is a structural schematic diagram of the present invention.

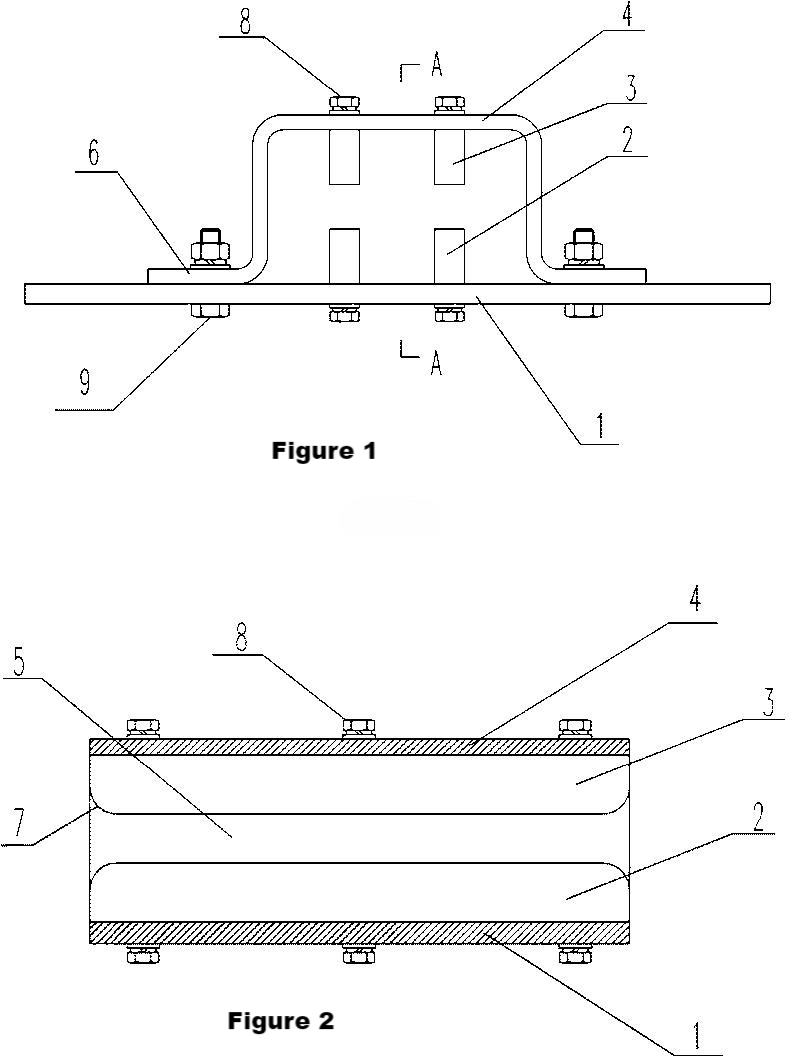

[0015] Figure 2 is a cross-sectional view of A-A in Figure 1.

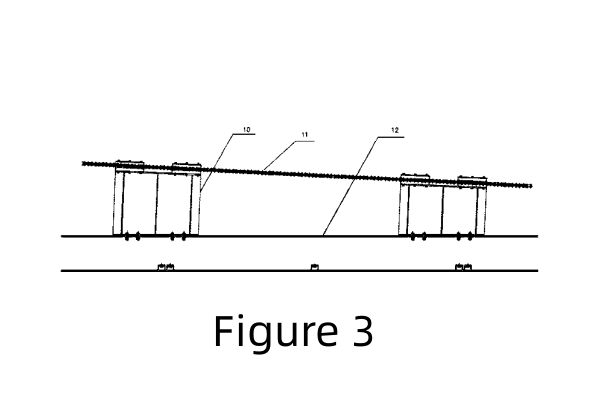

[0016] Figure 3 is a reference diagram of the usage status of the present invention.

[0017] In the figure: Bottom plate 1, lower nylon guide strip 2, upper nylon guide strip 3, protective cover 4, empty slot 5, fixed side plate 6, curved chamfer 7, screw 8, bolt 9, bracket 10, chain 11, rear beam 12o

Specific implementation method

[0018] The present device will be further described in conjunction with the accompanying drawings and specific embodiments.

[0019] In the embodiments shown in Figures 1 and 2, a chain support device for preventing chain detachment includes a base plate 1 installed on a fixed beam. The fixed beam is a fixed component at the bottom of the transmission chain, such as the rear beam or column of mechanical equipment. The bottom plate 1 is equipped with a lower nylon guide strip 2, and a protective cover 4 is also covered on the bottom plate 1. The protective cover 4 covers the top and two sides of the bottom plate 1, and there are openings for the chain to pass through at the front and rear ends of the protective cover 4. The top of protective cover 4 is connected downwards with an upper nylon guide strip 3, and the upper nylon guide strip 3 and lower nylon guide strip 2 correspond up and down, leaving an empty slot 5 for chain transmission. The upper and lower nylon guide bars are both elongated, with two parallel upper nylon guide bars vertically connected downwards on the protective cover, and two parallel lower nylon guide bars vertically connected upwards on the bottom plate, forming the chain support structure at both ends of the chain. The roller of the chain drives the chain by passing through the empty slots of the upper and lower nylon guide bars.

[0020] The side of the protective cover 4 extends horizontally to form a fixed side plate 6, which is connected to the bottom plate 1 through bolts 9 Fixed.

[0021] The front and rear ends of the upper nylon guide strip are equipped with arc-shaped chamfers 7, and the front and rear ends of the lower nylon guide strip are also equipped with arc-shaped chamfers 7. The arc-shaped chamfers at the ends of the upper nylon guide strip and the lower nylon guide strip form a trumpet shaped opening shape with an empty groove at the end.

[0022] The top of the upper nylon guide strip is fixed with screws 8 between the protective cover, and the screws are evenly distributed with three. lower

The bottom of the nylon guide strip and the anti bottom plate are fixed with screws 8, and the screws are evenly distributed with three.

[0023] The anti detachment chain supporting device can be applied to various mechanical equipment of chain transmission, not limited to mechanical parking equipment. When the chain is long, multiple chain support devices can be arranged in the middle, as shown in Figure 3. Two chain support devices are arranged side by side, and are installed on the rear beam 12 of the lifting device through bracket 10. During the transmission process of chain 11, two brackets 10 and four chain support devices are set. When the chain is inclined for transmission, the empty slots of the chain support device are inclined at the same angle.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com