Application of Leaf Chains

Leaf chain is a rollerless chain that is commonly used on forklift trucks and in other material handling applications. Leaf chain is constructed of steel link plates mounted side-by-side on pins. The contour of the link is the same figure-eight shape found on standard roller chains. The chain can flex at each pin. Leaf chain is used in tension linkage applications, where the chain is kept in tension and can be moved in either direction. Leaf chain is commonly used on forklift trucks and in other material handling applications. Leaf chain is also referred to as cable chain and balance chain.

Applications

There are different classes and applications for leaf chain. These include agricultural chain, conveyor chain, engineering steel chain, oil field chain, and power transmission chain.

Agricultural leaf chain is used for agricultural applications.

Conveyor leaf chain is specially designed for use in conveyor applications. This category includes roller chains with special attachments, flat-top leaf chains, and silent chains.

Engineering steel leaf chains are manufactured from machined and fabricated steel. This type of leaf chain can be used for a variety of industrial applications.

Oil field leaf chains are heavy-duty chains that are tested according to American Petroleum Institute (API) guidelines.

Power transmission leaf chains are used in power transmission drive applications.

Application Examples

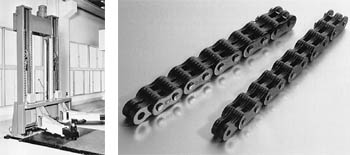

Leaf Chains are used for fork lift masts, as balancers between head and counterweight in machine tools, or for low-speed pulling (tension linkage). This type of chain is also called "Balance Chain," and is regulated by ANSI B29.8M, JIS B 1804, and ISO 4347. (See Figure 1.23.)

Figure 1.23 Leaf Chain and a Leaf Chain Application

Specifications

Specifications for leaf chains include series type. There are three main types of leaf chain series: AL series, BL series, and LL series.

AL series leaf chains have link plates that are the same contour and thickness as the ANSI roller chain pin links of the same pitch.

BL series leaf chains are designed to link plates that are thicker and have a larger contour than the AL series link plates of the same pitch. The BL series link plates and pins are the same as those of the ANSI roller chain of the next larger pitch.

LL series leaf chain is based on British Standard chain dimensions. LL series leaf chain conforms to the ISO 606 international standard.

Specialty leaf chain may also be available from some suppliers.

Construction and Features

These steel chains have a very simple construction: link plates and pins. The chain number indicates the pitch and the lacing of the links. (See Figure 1.24.) The chains also have the features shown below.

1. High tensile strength per section area. This allows the design of smaller equipment.

2. There are A- and B-type chains in this series. Both AL6 Series and BL6 Series have the same chain pitch as RS60 (19.05 mm), but they differ, as shown in Table 1.10.

3. These chains cannot be driven with sprockets.

Sprockets

Sheaves, not sprockets, are used to change the direction of these chains (Figure 1.25).

Lacing | 2×2 | 4×4 | 6×6 |

| | | |

Chain Size | AL622 | AL644 | AL666 |

Lacing | 2×3 | 3×4 | 4×6 |

| | | |

Chain Size | BL623 | BL634 | BL646 |

Figure 1.24 Leaf Chain Lacing Patterns

Table 1.10 Difference Between AL6 Series and BL6 Series | ||

AL6 Series | BL6 Series | |

Pin Diameter | 5.94 | 7.90 |

Plate Thickness | 2.4 | 3.2 |

Plate Height | 15.6 | 18.1 |

Plate Lacing | 2×2, 4×4 | 2×3, 3×4 |

Selection and Handling

1. In roller chains, all the link plates have higher fatigue resistance due to the compressive stress of press fits. In Leaf Chains, only two outer plates are press fit. Therefore, the tensile strength of Leaf Chains is high, but the maximum allowable tension is low. Use safety guards at all times, and be particularly alert to assure that the safety factor is in the manufacturer's catalog. Use extra safety factors where consequences of chain failure are severe.

2. The more plates used in the lacing, the higher the tensile strength. But this does not improve the maximum allowable tension directly; the number of plates used may be limited.

3. The pins articulate directly on the plates, and the bearing pressure is very high. The chains need regular lubrication. The use of SAE 30 or 40 machine oil is suggested for most applications.

4. When the chain speed is greater than 30 m/min., or if the chain is cycled more than 1,000 times in a day, it will wear very quickly, even with lubrication. In either of these cases, use RS Roller Chains.

5. AL-type should be used only under conditions in which:

1. There are no shock loads.

2. Wear is not a big problem.

3. Number of cycles is less than 100 a day.

Under other conditions, BL-type should be considered.

6. If you select a chain using a low safety factor, the stress in parts becomes higher. In this situation, if the chain is used in corrosive conditions, it may fatigue and break very quickly. If you're operating under these conditions, perform maintenance frequently.

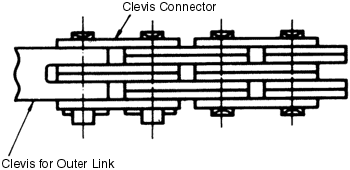

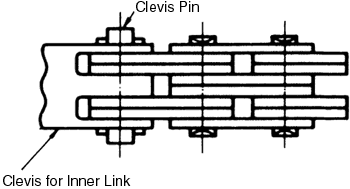

7. The shape of the clevis depends on the type of end link of the chain (outer link or inner link). Manufacturers produce clevis pins or clevis connectors, but typically, the user supplies the clevis (Figures 1.26 and 1.27). The strands should be furnished to length by the manufacturer. An incorrectly made clevis may reduce the working life of the chain. Contact the manufacturer or refer to the ANSI standard.

8. The sheaves are usually supplied by the user.

Figure 1.25 Leaf Chain Sheave

Figure 1.26 Leaf Chain

Figure 1.27 Leaf Chain

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com