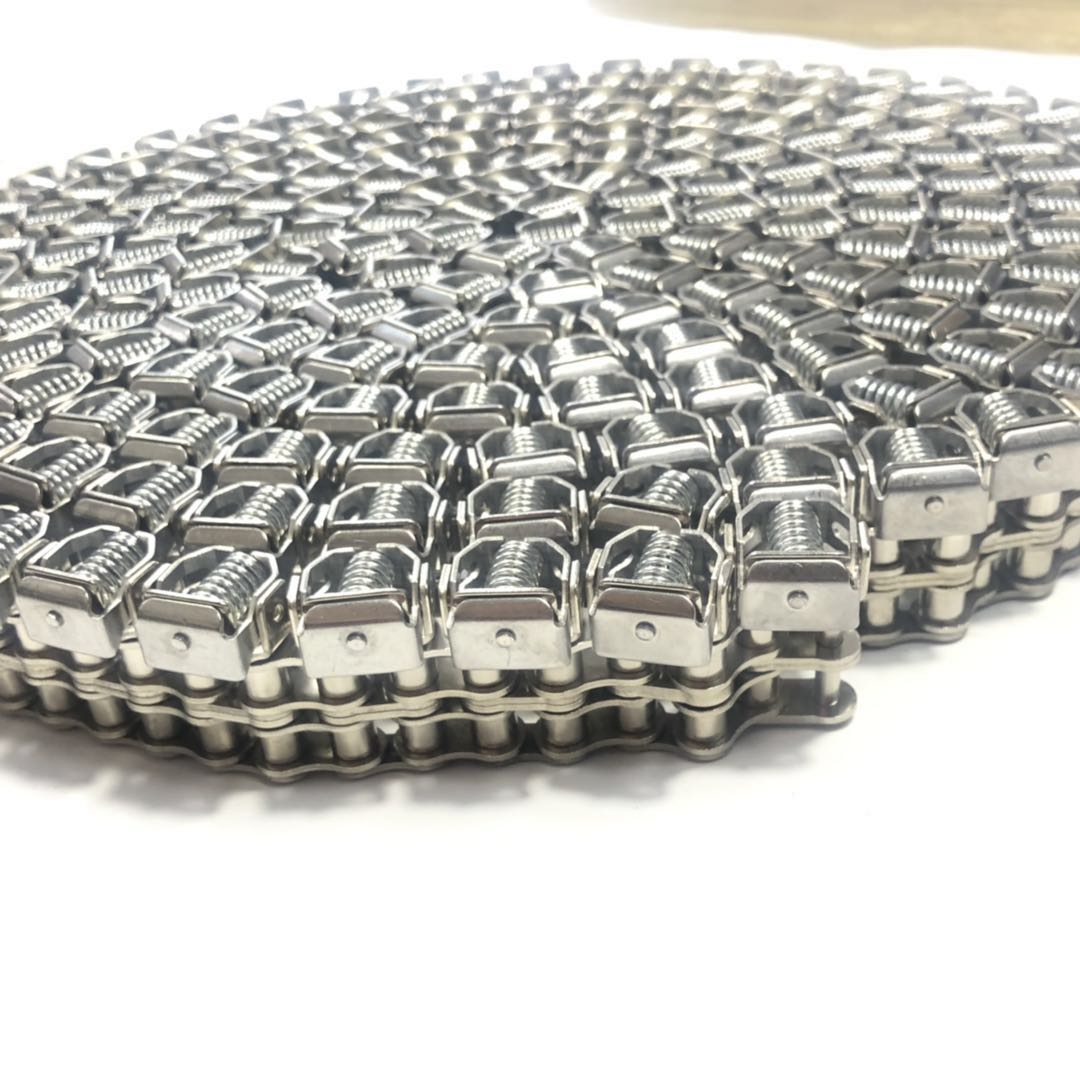

10B Gripper Conveyor Roller Chain for Agricultural Machinery

Gripper Chain for agricultural machinery (or simply referred to as clamping conveyor chains) are chains specially used for clamping and conveying crop stalks on agricultural machinery such as agricultural automatic threshing machines and semi feed grain combine harvesters. Therefore, these chains are also referred to as agricultural machinery feed chains and thresher chains. The clamping chain is divided into a chain structure without a sleeve and an inner link structure with a sleeve; Gripper Chain are widely used in rice harvesters. The basic structure of a chain is similar to that of a sleeve roller chain, characterized by a high pointed toothed chain plate and a large inner width of the inner section to increase the width and firmness of the clamping. During operation, the clamping chain and guide rail jointly form a support and clamping mechanism for the crop stalks, and rely on the operation of the chain to achieve the goal of evenly transporting the stalks. Gripper Chain typically have a low speed when used, and bear less tensile load during operation. They are ultra light functional conveyor chains. The clamping conveyor chain can be used in multiple rows in parallel. In addition, according to actual needs, as long as the gap between the chain hinge and the inner and outer chain plates is increased, the clamping chain can also have the function of side bending.

The included angle of the top teeth on the clamping chain plate is an important parameter, which has a great relationship with the working performance of the chain. When in use, whether the stalks can uniformly advance synchronously with the conveying chain and make the space between the adjacent chain plate teeth as large as possible depends on the value of the included angle between the top teeth. This is because the included angle of the top teeth is related to the stem space and the size of the clamping force. The included angle of the top teeth is determined according to the actual use requirements of different harvesters, so the standard does not specify the included angle value. Generally, the commonly used included angle values include 70 °, 90 °, 60 °, and 75 °. However, the commonly used chain plate shape and size requirements are already specified in JB/T 8883. Currently in use for agricultural machinery, there are clamping conveyor chains (especially some Gripper Chain with large inner section widths), as well as inner chain plates with a hole flanging structure. The hole flanging of the inner chain plate integrates the sleeve and the inner chain plate, and the sleeve component is omitted from the chain structure. The advantage of this structure is that there is no problem of the connection between the chain plate and the sleeve, but in order to ensure the overall firmness of the chain, The riveting quality of the pin shaft on the outer chain link must be guaranteed. However, inner chain plates with a perforated structure can generally only be made of low carbon structural steel, and the tensile strength of this type of chain plate is bound to be lower than that of inner chain plates made of medium carbon structural steel (generally without a perforated structure), which will reduce the tensile performance of the entire chain. Therefore, more and more new harvester models use Gripper Chain with inner chain plates that tend to adopt a non turning hole structure, while using a clamping chain with a sleeve makes the chain more stable and stronger. Due to the relatively large amount of Gripper Chain with perforated structures on the market, the chains with perforated chain plate structures are still retained in JB/T 8883-201X.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com