GIDI scraper chain are made by die forging, hardening and tempering and carburization. Its hardness can be up to HRC 50. The scraper chain is suitable for conveyor device used in bulk materials such as cement, powder, grain powder, sand and coal in powderk pellet or small lump styles.

In order to make scraper chains with improved quality and extended service life, we adopt automatic welding robots to weld the bushing and sidebar together. The precision equipment guarantees uniform and stable welding quality. Meanwhile, we conduct inspections according to the Quality Control Standard of international leading roller chain manufacturers. Additionally, according to the proportion of 5%, our welded steel chain products undergo conduct destructive tests to ensure approved welding quality. Our patented high frequency induction heating treatment for the pins offers higher strength while improving the wearing resistance.

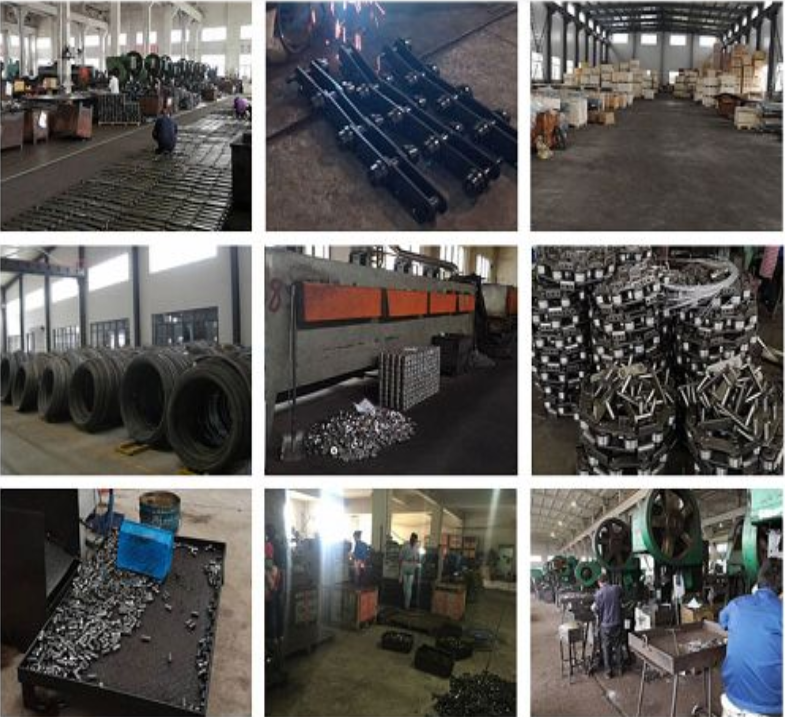

Why Choose Us ?

1. More than 10 years' experience in Roller chain

2. Over 15000 m Factory is equipped with 100 advanced Machines

3. Have whole production line from material, cutting, punching, heat-treating, assembling to ensure quality control

4. With 4 production lines, 180 employees can products 60000 meters monthly

5. With 6 QC inspectors and 4 R&D engineers will provide perfect OEM&ODM service

6. Have the certificate of ISO 9001-2015

7. We enjoy a hot market in most parts of Europe, America, South Africa, Southeast Asia

8. Have reliable raw material suppliers and have been cooperated with us for years

Packing & Delivery

Packing Details : Polywood case or Pallet.

We can also pack the chain as per request.