The basic requirements for the performance of chain materials are high strength and good wear resistance, and the transportation chain is no exception. However, compared with the transmission chain, the conveying chain has a slower speed and a larger load capacity, and the total length of the chain used and the number of chain links are large, so the quality of the chain is large. Especially for large roller conveyor chains, because the quality of large rollers occupies a larger proportion in the chain, the problem of large quality is even more prominent. A chain with an excessive mass will greatly increase the tension received by the chain, thus increasing the consumption of ineffective power. Therefore, reducing the quality of the transportation chain itself is an important issue in the design of the transportation chain.

Roller chains have the advantages of reducing friction, noise, and smoothing without grease. At present, the strength of engineering plastics is still low, so it can only be used to make chains for small conveyors, and rollers on lighter conveyor chain attachments. The sleeves and rollers of the chain made of oil-containing powder metallurgy materials can also have the effect of reducing friction and not being smooth, and the weight of powder metallurgy materials is lighter than steel, so it has also been developed. Of course, a chain with good working performance under high temperature and corrosive conditions is also guaranteed by the use of special performance materials.

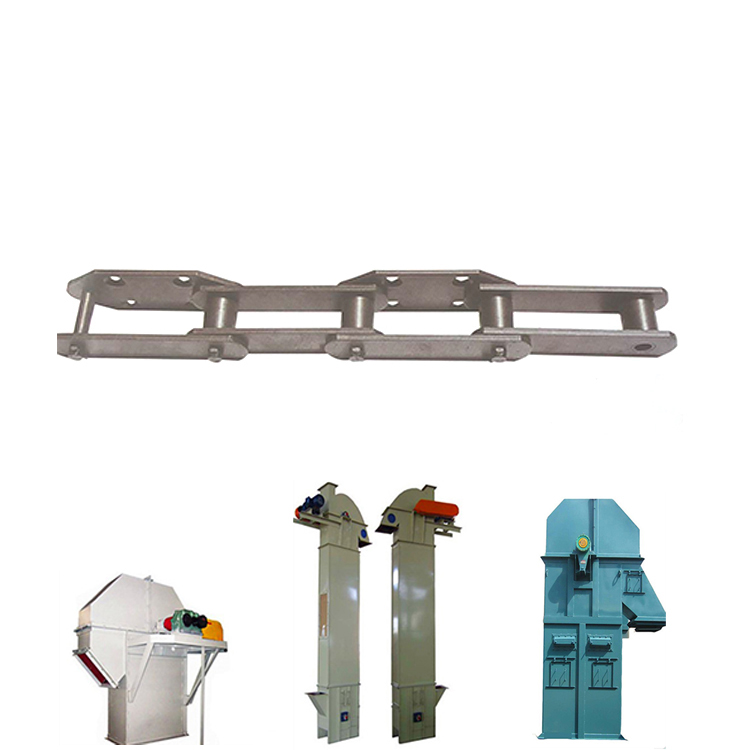

Accurate roller chains, bushing chains, roller chains, bushing chains for transmission, long pitch roller chains for transmission, heavy-duty curved plate roller chains for transmission, transmission chains for oil rigs; toothed transmission chains; casting, Punching hook chain; conveying roller chain, conveying long pitch roller chain, conveying flat top chain, solid pin, hollow pin conveying chain, conveying chain with attachments; die forging, punching detachable chain (suspended Transportation chain); plate chain for lifting, round link chain; corrosion-resistant stainless steel chain, plastic chain, powder metallurgy chain; continuously variable speed chain; anti-skid chain.

The chain is evolved from the early malleable cast iron chain, S type is ∞-shaped chain plate, C type is straight chain plate. It is suitable for the places where the chain plate slides on the track during the transportation of crops and articles, and the embossed boss in the middle of the C-shaped chain plate (the boss should be higher than the pin rivet head) is suitable for in-plane operation of the chain Use the boss as the sliding pair to touch the track to prevent the end of the pin from wearing and avoiding the failure of the chain.