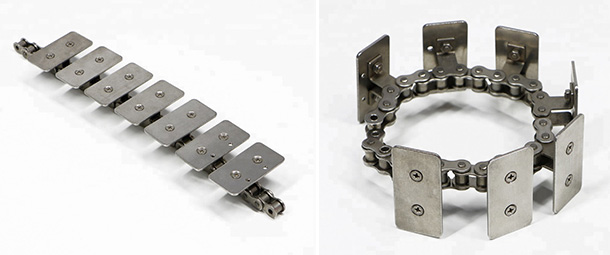

Food Packing Machine Chain is one kind of conveyor chain.These chains are one part of packing machine.And it is used in food production factory. It usually use 304ss or 316ss stainless steel material.There are many types of food packing machine chains.These chains are usually special. GIDI CHAIN LIMITED can do the chain as per customer's request with high quality.Follow is one sample of food packing machine chain.If you need more other information about food packing machine chains.Welcome to contact us.

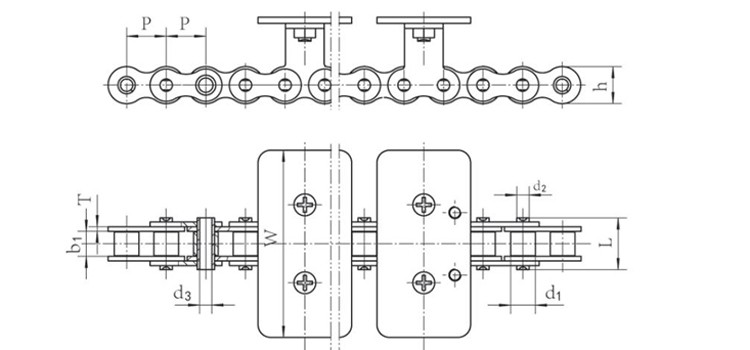

| Chain No. | Pitch | Roller diameter | Width between iner plates | Pin | Plate | Minimum tensile strength | ||||

| P mm | d1(max)mm | ib,(min) mm | d2 mm | d3 mm | l mm | W mm | h mm | t/T mm | Fu(min) kN | |

| 08BSS-T | 12.7 | 8.51 | 7.75 | 4.45 | 4.5 | 17 | 60 | 11.8 | 1.65 | 12 |

Applications of Food Packing Machine Chain

Food packing machine chains, also known as conveyor chains or packaging chains, play a critical role in the food packaging industry by facilitating the movement of packaged food products through various stages of the packaging process. These chains are designed to meet the specific requirements of hygienic and sanitary conditions while ensuring efficient and reliable transportation. Here are some common applications of food packing machine chains:

Conveyor Systems: Food packing machine chains are used in conveyor systems to transport packaged food items between different stages of the packaging process, such as filling, sealing, labeling, and packaging. They ensure smooth and continuous movement of products on the production line.

Filling Stations: In automated filling stations, chains are utilized to move containers (such as bottles, cans, or pouches) under the filling nozzles. This ensures accurate and consistent filling of food products, such as liquids, powders, or granules, into the packaging.

Sealing and Capping: Chains are involved in moving containers through sealing and capping stations, where caps or lids are securely applied to the packaging. Proper alignment and controlled movement are essential to ensure the integrity of the seal.

Labeling and Printing: Food packing machine chains transport containers to labeling and printing stations, where labels with product information, barcodes, and other markings are applied. Precise positioning is crucial to ensure accurate labeling.

Inspection and Quality Control: Chains are used to move packaged food products through inspection and quality control stations, where visual checks, measurements, and other assessments are performed to ensure product quality and compliance with standards.

Sorting and Diverting: Conveyor chains are employed in sorting and diverting systems that route packaged food items to different packaging lines or destinations based on specific criteria, such as product type, size, or destination.

Packaging and Wrapping: Chains play a role in moving packaged food items into packaging materials, such as boxes, bags, or trays, for the final packaging and wrapping process. This step ensures that the products are properly contained and ready for distribution.

Palletizing and Depalletizing: Chains are used in palletizing systems to transport packaged food products onto pallets in a specific pattern or arrangement. Similarly, they assist in depalletizing, where products are removed from pallets for further processing or distribution.

End-of-Line Packaging: Food packing machine chains are employed at the end of the packaging line to facilitate the movement of packaged products to storage areas or distribution points.

Freezing and Cooling: In some cases, conveyor chains are used to transport packaged food products through cooling tunnels or freezing chambers, where products are rapidly cooled or frozen to extend shelf life.

Food packing machine chains are designed with materials and coatings that comply with food safety regulations and hygiene standards. They are constructed to withstand the demands of food processing environments while maintaining the integrity of packaged products. Proper maintenance, cleaning, and lubrication are crucial to ensure the chains' optimal performance and to prevent contamination of the packaged food items.