As a high quality roller chain supplier, GIDI CHAIN LIMITED developed fastly in recent 8 years. Now we provide a wide range of roller chain using in many industries including material handling equipment, palm oil mill industry, sugar mill industry, engineering machinery, automatic production line, packing machine, mining&metallurgy, grain machine, mylar processing industry, beer bottling line, paver machine, car parking industry, and other conveyor and transmission equipment.

Roller chain is composed by four parts.They are roller ,bush,plate and pin. The material can be carbon steel or 304SUS(316SUS)stainless steel The carbon steel main materials are as follow:

Plate:40Mn,45Mn,40Cr.

Roller:10#,20#,45#,40Cr.

Bush:10#,20#.

Pin:20CrMnMo,30CrMnTi,40Cr.

We provides a high tensile strength roller chain advantage for hundreds of applications coping with operating conditions that are hot or cold, wet or dry, dusty or requiring cleanliness and all of these solutions combine excellent wear resistance and fatigue resistance with a long, reliable working life.

European Standard Roller Chains

1. BS/DIN Standard Short Pitch Power Transmission Roller Chains: 03B-56B

2. BS/DIN Standard Short Pitch High Performance Roller Chain

3. (all parts made of special alloy steel, with solid seamless bushes and wide waist linkplates)

4.BS/DIN Standard Short Pitch Self-Lubricating Roller Chains (Maintenance Free Chains)

5. BS/DIN Standard Marine Engine Roller Chains (Marine Engine Chain): 32BM-72MBS/DIN Standard Short Pitch Straight

Link Plate Roller Chains: C08B-C48B

6. BS/DIN Standard Short Pitch Bushed Chains (Rollerless)

7. BS/DIN Standard Double Pitch Transmission Roller Chains: 208B-232BL

American Standard Roller Chains

1. ANSI Standard Short Pitch Power Transmission Roller Chains (and Bushed Chains as well): 25-240

2. ANSI Standard Short Pitch High Performance Roller Chain

3. (all parts made of special alloy steel, with solid seamless bushes and wide waist linkplates)

4. ANSI Standard Short Pitch Straight Linkplate Roller Chains: C40-C240

5. ANSI Standard Short Pitch Heavy Duty Roller Chains: 60H-240H

6. T Series Super Roller Chains: T40-T140

7. HT Series Super Roller Chains: HT60-HT140

8. SHT Series Super Roller Chains: SHT80-SHT140

9. ANSI Standard Short Pitch Bushed Chains (Rollerless)

10. Roller Chains for Chain Couplings: 4012-12022

11. ANSI Standard Double Pitch Transmission Roller Chains: A2040-A2120

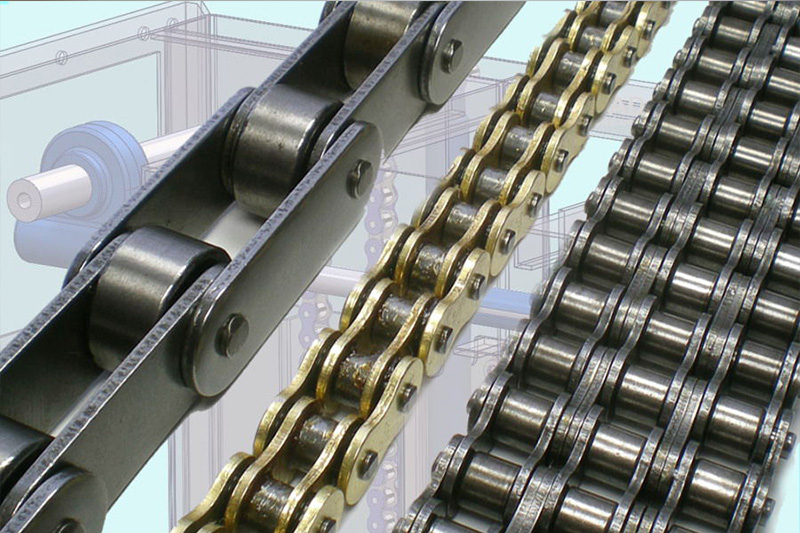

Roller chain is one kind of power transmisssion component. It is used in low- to mid-speed drives at around 600 to 800 feet per minute and widely used for general industrial applications. They are available in simplex, duplex and triplex with riveted or cottered.

Customer Roller Chain China Manufacturer - GIDI CHAIN

GIDI CHAIN LIMITED locates in Zhuji City, Zhejiang province, and we has branch factory in Changzhou. We supply lots of roller chains, conveyor chains, welded chains, forged chains, totaling over 3000 varieties. And 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America.

Our company owns more than 100 sets of advanced and professional manufacturing equipments, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging The products completely conform to the ISO, ANSI, BS, DIN, JIS international standards and the national industry standards. GIDI has set up a complete set of a quality management system which is provided with advanced inspection and test equipment. Since 2001, GIDI has been successfully certified by ISO9001 Quality Management System, SGS inspection and BV inspection.

INDUSTRIAL ROLLER CHAIN FAQ USER GUIDE

What is a roller chain?

A roller chain, also known as a roller link chain or simply a chain, is a mechanical component used for transmitting power or conveying motion between two or more rotating shafts. It is a type of transmission chain commonly used in various industrial applications, including machinery, vehicles, and equipment.

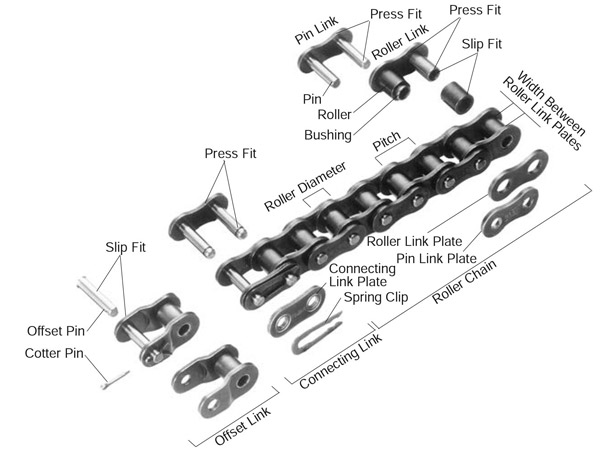

A roller chain consists of a series of interconnected links, typically made of metal, that form a flexible and durable loop. The chain consists of inner links and outer links that alternate in a regular pattern. The inner links have two inner plates with bushings or bearings fitted inside, while the outer links have two outer plates.

The main feature of a roller chain is the presence of small cylindrical rollers that sit between the inner plates of the chain. These rollers allow the chain to smoothly engage with the sprockets (gear-like wheels) that are mounted on the shafts. As the chain moves, the rollers rotate, reducing friction and enabling efficient power transmission.

Roller chains are designed to handle high loads, resist wear, and provide reliable operation. They are available in various sizes and configurations, allowing them to be used in a wide range of applications. Common uses include power transmission in machinery, such as conveyors, motorcycles, bicycles, industrial equipment, and even some automotive applications.

Features

Common features for roller chain include attachment chain, double pitch, oversized roller, rollerless, offset link, heavy duty, self-lubricating, corrosion resistant, and flexible.

Roller chain with an attachment type includes standard straight, standard bent, wide contour straight, wide contour bent, and extended pins.

Configurations

Standard configurations for roller chain include single, double, triple, quadruple, and quintuple or higher. A single configuration has one chain strand. A double configuration has two chain strands, and so on.

Roller chain comes in a wide variety of metal and plastic materials. Common materials of construction include steel or hardened steel, stainless steel, nylon, acetal, polypropylene, and plastic or metal combination.

Types of Industrial Roller Chain

There are several types of roller chains available, each designed for specific applications and operating conditions. Here are some commonly used types of roller chains:

Standard Roller Chain: This is the most common type of roller chain, also known as an ANSI chain. It follows the standards set by the American National Standards Institute (ANSI) and is widely used in general industrial applications.

Heavy-Duty Roller Chain: This type of chain is designed to handle higher loads and provide increased strength and durability. It is commonly used in heavy machinery, construction equipment, and mining applications.

Double-Pitch Roller Chain: This chain has a longer pitch (distance between rollers) than standard roller chains. It is often used in applications where slower speeds and lighter loads are encountered, such as conveyor systems.

Silent Chain: Silent chains, also known as inverted tooth chains or inverted tooth silent chains, are designed to reduce noise and vibration during operation. They are commonly used in power transmission applications, such as automotive timing systems and industrial machinery.

O-Ring Chain: O-ring chains have rubber O-rings inserted between the inner and outer plates. The O-rings act as seals, retaining lubrication and preventing dirt and debris from entering the chain. O-ring chains are commonly used in motorcycles and other applications where maintenance and durability are important.

Stainless Steel Chain: Stainless steel chains are made from corrosion-resistant stainless steel materials, making them suitable for applications in harsh environments, food processing, and pharmaceutical industries.

Nickel-Plated Chain: Nickel-plated chains have a thin layer of nickel coating on the outer plates to provide corrosion resistance and improve aesthetics. They are often used in applications where some level of corrosion protection is required.

Attachment Chain: Attachment chains have specialized attachments or extended pins on the outer plates to accommodate specific applications. They are commonly used in conveying systems, such as in the automotive industry or for handling materials.

These are just a few examples of roller chain types, and there are variations and specialty chains available to suit specific requirements. It's essential to choose the appropriate type of roller chain based on the specific application, load requirements, environmental conditions, and industry standards.

What is Industrial Roller Chain used for?

Industrial roller chains are widely used in various applications across industries. Some common uses of industrial roller chains include:

Power transmission: Roller chains are extensively used for transmitting power from one rotating shaft to another. They are employed in machinery such as conveyors, agricultural equipment, printing presses, packaging machines, material handling systems, and industrial automation systems.

Conveyors: Roller chains are widely utilized in conveyor systems to move materials or products along a production line. They provide a reliable and efficient means of transferring goods in industries such as manufacturing, food processing, mining, and logistics.

Automotive industry: Roller chains find application in the automotive sector, especially in motorcycles, where they are used for power transmission between the engine and the rear wheel. They are also used in some automotive engine timing systems.

Agriculture and forestry: Roller chains are used in agricultural machinery, including tractors, harvesters, and crop processing equipment. They are employed for powering various functions such as transmission, auger systems, grain handling, and more. In the forestry sector, roller chains are used in chainsaws and logging equipment.

Material handling and lifting equipment: Roller chains are utilized in equipment like forklifts, cranes, hoists, and elevators to facilitate the movement and lifting of heavy loads.

Mining and construction: In mining and construction equipment, roller chains are used for power transmission and conveying materials. They are employed in applications such as bucket elevators, loaders, excavators, and crushers.

Oil and gas industry: Roller chains are utilized in oil and gas exploration and production equipment, including pumps, compressors, and drilling machinery.

Manufacturing and industrial machinery: Roller chains play a vital role in various manufacturing processes, including assembly lines, machine tools, textile machinery, and paper manufacturing.

Food processing and packaging: Roller chains designed for food-grade applications are used in food processing and packaging machinery, ensuring hygienic and reliable operation.

Robotics and automation: Roller chains are utilized in robotic systems and automation equipment to transmit power and facilitate movement.

These are just a few examples of the numerous applications of industrial roller chains. Their durability, strength, and efficient power transmission capabilities make them indispensable components in a wide range of industries.

How Does a Roller Chain Work?

Roller chains consist of a series of interconnected links, including inner links and outer links, that form a flexible loop. The inner links have inner plates with bushings or bearings fitted inside, while the outer links have outer plates. The chain engages with teeth on the sprockets, which are gear-like wheels.

When power is applied to the drive sprocket, it rotates, causing the chain to move. As the chain moves, the rollers between the inner plates rotate, engaging with the teeth of the sprocket. This rotation of the rollers reduces friction and enables smooth power transmission. The speed and direction of the driven shaft are determined by the size and ratio of the sprockets.

Proper chain tension is important for smooth operation. Tension can be adjusted by altering the distance between the drive and driven sprockets or using tensioners or idler sprockets. Lubrication is also necessary to reduce friction, prevent wear, and ensure the chain functions properly.

Overall, roller chains are reliable and efficient components used for power transmission and motion transfer in various applications. Their design allows them to withstand high loads and provide reliable operation in industries such as agriculture, manufacturing, and transportation.

How to Size and Select Roller Chain ?

Sizing and selecting the appropriate roller chain for a specific application involves considering several factors. Here are the general steps to follow:

Determine the power requirements: Calculate or estimate the power or torque that needs to be transmitted through the chain. This can be based on the driven load, speed, and desired operating conditions.

Identify the drive and driven sprockets: Determine the number of teeth on the drive (input) and driven (output) sprockets. This information is crucial for selecting the appropriate chain size.

Determine the center distance: Measure the distance between the shaft centers of the drive and driven sprockets. This center distance affects the chain length required.

Consider the environmental conditions: Evaluate the operating environment for factors such as temperature, presence of contaminants, corrosion, and special requirements like food-grade applications. This information will help choose the suitable material and surface treatment for the chain.

Determine the chain type and pitch: Based on the power requirements, sprocket sizes, and environmental conditions, select the appropriate chain type and pitch. The pitch refers to the distance between the centers of adjacent roller pins and is typically measured in inches (e.g., 0.625", 0.750", etc.) or in metric units (e.g., 8 mm, 10 mm, etc.).

Calculate the chain length: Calculate the required chain length by considering the number of chain links needed. This depends on the center distance, the number of teeth on the sprockets, and the chain pitch. There are formulas available for this calculation, or you can use online chain length calculators.

Consider additional factors: Depending on the specific application, you may need to consider factors like allowable elongation, fatigue strength, special attachments or features (e.g., corrosion-resistant coatings, self-lubricating properties), and any specific industry or regulatory requirements.

Consult manufacturer catalogs or guidelines: Refer to manufacturer catalogs or guidelines for the selected chain type and pitch to ensure it meets the calculated specifications and matches the requirements of your application.

It's important to note that the above steps provide a general guideline, but specific applications may require additional considerations or expert advice. If in doubt, consulting with a chain manufacturer or a knowledgeable engineer can help ensure proper sizing and selection of the roller chain.