Engineered Steel Chains: A Comprehensive Overview

Engineered steel chains are meticulously crafted chains designed for use in demanding industrial applications. Tailored to withstand extreme conditions such as high temperatures, corrosive chemicals, and heavy loads, these chains prioritize durability and longevity. Their robust construction makes them indispensable in industries where reliability is paramount.

Types of Engineered Steel Chains:

American Standard Engineered Steel Chains without Rollers:

Description: Mechanical chains comprising steel links designed for diverse industrial applications, relying on interlocking links for power transmission.

Applications: Widely used in conveyor systems, agricultural machinery, and construction equipment where reliable power transmission is critical.

Material: Typically crafted from high-quality carbon or alloy steel, with potential heat treatment or surface coatings for enhanced strength and corrosion resistance.

Top Plate Conveyor Chains:

Description: Conveyor chains with plates on the top surface, serving as platforms for products or materials as they move along the conveyor.

Applications: Commonly utilized in material handling industries such as food and beverage, automotive, and packaging.

Material: Typically made of steel or stainless steel, customizable with various plate sizes, spacing, and chain widths.

Bush Chains:

Description: Chains standardized according to DIN 8164, utilizing solid bushings instead of rollers for enhanced wear resistance.

Applications: Versatile applications, including conveyors, agricultural machinery, construction equipment, and automotive systems.

Material: Crafted to DIN 8164 specifications, comparable to roller chains according to ISO 606 standards.

ATC Chains:

Description: Tailor-made chains for tool storage and organization in CNC machining centers, offering customized solutions.

Applications: Ideal for small tool attachment systems and applications requiring high storage capacity in limited spatial conditions.

Material: Custom-built using standard roller chains or a combination of roller chains and double-pitch chains.

Inverted Tooth Chains:

Description: Power transmission chains with unique tooth shapes, reducing noise and vibration during operation.

Applications: Widely used in industrial machinery and automotive applications where quiet operation is essential.

Material: Typically made of high-strength steel, suitable for transmitting power over long distances and at high speeds.

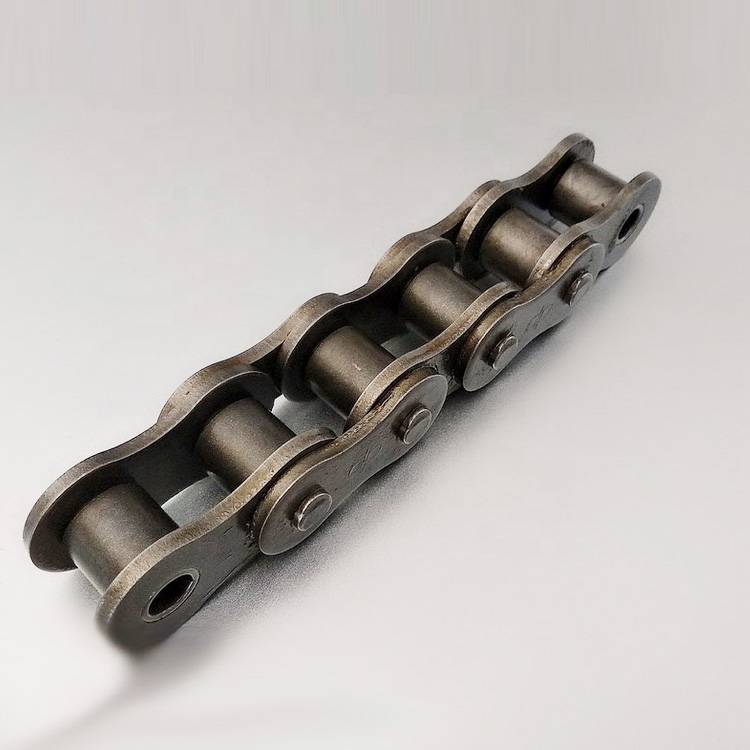

Side Bow Chains:

Description: Roller chains with a unique side bow configuration for enhanced flexibility, shock absorption, and reduced wear.

Applications: Ideal for conveyor systems, packaging machinery, printing presses, and high-speed industrial applications.

Material: Crafted with special offset plates to create a curved or bowed shape for improved performance.

Pusher Dog Chains:

Description: Chains designed for securing general cargo during transport, featuring interlocking pusher dogs or plates.

Applications: Widely used in the transport industry to prevent cargo from shifting or falling off during transit.

Material: Crafted from high-strength steel to withstand heavy loads and extreme conditions.

Conclusion:Engineered steel chains offer a diverse range of solutions catering to specific industrial needs. From power transmission in machinery to securing cargo during transport, each type serves a unique purpose, ensuring efficiency and reliability across various applications. The choice of an engineered steel chain depends on the specific demands of the industrial process or task at hand.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com