Steel Draw Bench Chain

This range of drive chain is designed to drag the steel draw bench which is commonly used in steel plants, steel pipe making plants, structural steel cold drawing plants, as well as many other industrial uses. It is applicable for carrying of high impact load under low speed conditions.

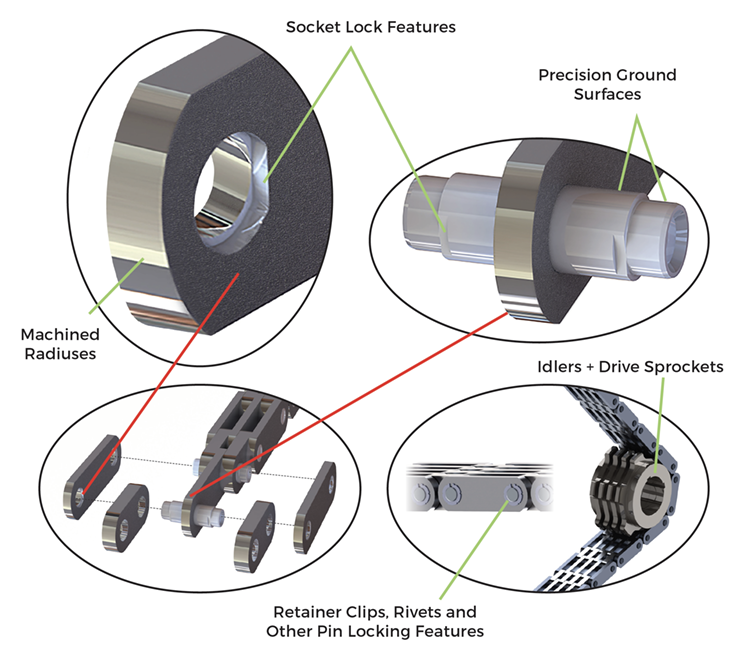

The steel draw bench chain features simple and rational structure design. It primarily consists of the chain plate and the pin.

The chain plates or sidebars are made using spring steel alloys with high fatigue resistance. After integral hardening and tempering, the sidebars are created with a hole at each end by a precision boring machine. The precision machining center ensures exactly the same hole pitch and bore size, thus allowing each sidebar to carry equal load.

The pin rolls also undergo integral hardening and tempering, as well as precision processing for the same external diameter. Thereafter, they are processed by high frequency induction heating treatment to increase surface hardness, and are precision ground to offer smooth finish. Due to these processes for the pins and side plates, the steel draw bench chain is provided with improved lifespan.

A steel draw bench chain is an essential component in the operation of a draw bench, particularly in the context of metalworking and cold drawing processes. The draw bench is a machine used to reduce the diameter and increase the length of various materials, such as bars, tubes, or wires, through a drawing process.

The steel draw bench chain plays a crucial role in the functioning of the draw bench. Here's a brief overview of its characteristics and functions:

Material and Construction: The draw bench chain is typically made of steel due to its strength, durability, and resistance to wear and tear. The construction of the chain is designed to withstand the forces and stresses involved in the drawing process.

Linkage and Engagement: The chain consists of interconnected links that form a continuous loop. The links are engineered to engage with the drawing trolley or carriage, which holds the material being drawn. As the chain moves, it pulls the drawing trolley along a specified path through the draw bench.

Motor-Driven Operation: The draw bench chain is driven by a motor that provides the necessary power to move the chain and, consequently, the drawing trolley. The motor is a critical component that ensures a controlled and consistent drawing process.

Guidance Mechanism: The draw bench chain is guided along a predetermined path within the draw bench machine. Proper guidance is essential to ensure the accurate and repeatable movement of the drawing trolley through the drawing dies.

Tension Control: Tension control is crucial to maintain the proper grip on the material being drawn. The draw bench chain must be appropriately tensioned to prevent slipping or uneven drawing, ensuring a uniform reduction in diameter and consistent results.

Compatibility and Adaptability: The design of the draw bench chain should be compatible with the specific requirements of the draw bench machine. Different draw bench applications may require chains of varying lengths, strengths, and configurations.

Wear Resistance: Given the repetitive and abrasive nature of the drawing process, the draw bench chain should be designed for high wear resistance. This ensures a longer service life and reduces the frequency of maintenance and replacement.

In summary, the steel draw bench chain is an integral part of the draw bench machine, facilitating the controlled movement of the drawing trolley during the metal drawing process. Its construction, motor-driven operation, guidance mechanisms, and compatibility features are essential for achieving precise and consistent results in the cold drawing of metal materials.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com