Roller Chain Basics and Sizes

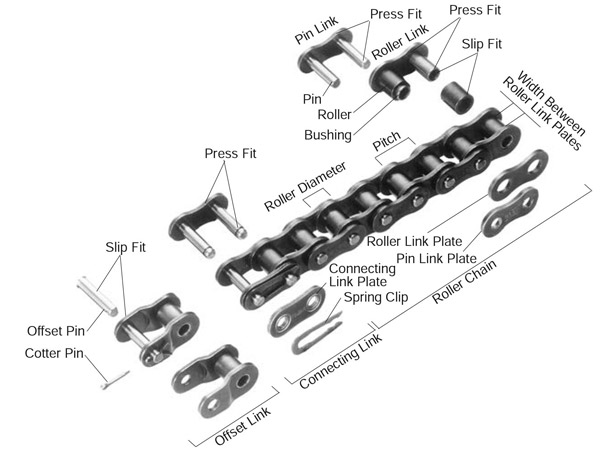

Roller chains, also known as bush roller chains, are the most commonly used type of chain drive for transmitting mechanical power in various domestic, industrial, and agricultural machinery applications. These versatile chains find use in conveyors, wire- and tube-drawing machines, printing presses, automobiles, motorcycles, bicycles, and more. Roller chains consist of a series of short cylindrical rollers connected by side links and are driven by toothed wheels called sprockets. They are celebrated for their simplicity, reliability, and efficiency in power transmission.

Roller chains typically operate in low- to mid-speed drives, typically at speeds ranging from 600 to 800 feet per minute. However, at higher speeds, typically around 2,000 to 3,000 feet per minute, V-belts are often preferred due to reduced wear and noise concerns.

A bicycle chain is a common example of a roller chain. Bicycle chains may include a master link or require a chain tool for installation and removal. In contrast, most motorcycles employ a similar but larger and stronger chain. However, motorcycles sometimes opt for toothed belts or shaft drives, offering lower noise levels and reduced maintenance requirements.

Certain automobile engines utilize roller chains to drive the camshafts, while high-performance engines may opt for gear drives. Starting in the early 1960s, some manufacturers also began incorporating toothed belts.

It's worth noting that forklifts utilize chains in conjunction with hydraulic rams to raise and lower carriages. These chains are not considered roller chains but rather classified as lift or leaf chains.

Chainsaw cutting chains, though superficially resembling roller chains, are more closely related to leaf chains. They are driven by projecting drive links, which also serve to position the chain on the bar.

In a unique application, a pair of motorcycle chains is used in the Harrier jump jet. This chain drive, powered by an air motor, facilitates the rotation of movable engine nozzles, enabling the aircraft to transition between hovering and forward flight, a technology known as "thrust vectoring."

Bicycle Chain Wear

Bicycle chains, especially those used with derailleur gears, can experience wear and failure. These chains have barrel-shaped pins that interact with bushings, allowing the chain to bend and twist to accommodate gear changes. This design can lead to pin and bushing contact points wearing down over time, eventually causing the chain to fail.

In contrast, hub-geared systems (e.g., Bendix 2-speed, Sturmey-Archer AW) are less prone to chain failure. These systems feature parallel pins with more significant contact surfaces with the bushings. Additionally, hub-gear systems offer complete enclosure, aiding lubrication and protecting against debris.

Chain Strength

The strength of roller chains is commonly measured in tensile strength, indicating the maximum load a chain can withstand before breaking under a single-time load. Besides tensile strength, a chain's fatigue strength is critical, influenced by factors like the quality of steel, heat treatment, pitch hole fabrication, shot peen coverage, linkplate thickness, and design.

For continuous drive applications, it's advisable not to exceed 1/6 or 1/9 of the chain's tensile strength, depending on the type of master links used. Operating beyond these thresholds can result in premature chain failure due to linkplate fatigue.

| ASME/ANSI B29.1-2011 Roller chain standard sizes | ||||

| Size | Pitch | Maximum roller diameter | Minimum ultimate tensile strength | Measuring load |

|---|---|---|---|---|

| 25 | 0.250 in (6.35 mm) | 0.130 in (3.30 mm) | 780 lb (350 kg) | 18 lb (8.2 kg) |

| 35 | 0.375 in (9.53 mm) | 0.200 in (5.08 mm) | 1,760 lb (800 kg) | 18 lb (8.2 kg) |

| 41 | 0.500 in (12.70 mm) | 0.306 in (7.77 mm) | 1,500 lb (680 kg) | 18 lb (8.2 kg) |

| 40 | 0.500 in (12.70 mm) | 0.312 in (7.92 mm) | 3,125 lb (1,417 kg) | 31 lb (14 kg) |

| 50 | 0.625 in (15.88 mm) | 0.400 in (10.16 mm) | 4,880 lb (2,210 kg) | 49 lb (22 kg) |

| 60 | 0.750 in (19.05 mm) | 0.469 in (11.91 mm) | 7,030 lb (3,190 kg) | 70 lb (32 kg) |

| 80 | 1.000 in (25.40 mm) | 0.625 in (15.88 mm) | 12,500 lb (5,700 kg) | 125 lb (57 kg) |

| 100 | 1.250 in (31.75 mm) | 0.750 in (19.05 mm) | 19,531 lb (8,859 kg) | 195 lb (88 kg) |

| 120 | 1.500 in (38.10 mm) | 0.875 in (22.23 mm) | 28,125 lb (12,757 kg) | 281 lb (127 kg) |

| 140 | 1.750 in (44.45 mm) | 1.000 in (25.40 mm) | 38,280 lb (17,360 kg) | 383 lb (174 kg) |

| 160 | 2.000 in (50.80 mm) | 1.125 in (28.58 mm) | 50,000 lb (23,000 kg) | 500 lb (230 kg) |

| 180 | 2.250 in (57.15 mm) | 1.460 in (37.08 mm) | 63,280 lb (28,700 kg) | 633 lb (287 kg) |

| 200 | 2.500 in (63.50 mm) | 1.562 in (39.67 mm) | 78,175 lb (35,460 kg) | 781 lb (354 kg) |

| 240 | 3.000 in (76.20 mm) | 1.875 in (47.63 mm) | 112,500 lb (51,000 kg) | 1,000 lb (450 kg) |

Chain Standards

Standards organizations such as ANSI and ISO establish guidelines for the design, dimensions, and interchangeability of transmission chains. For instance, ANSI standard B29.1-2011 provides specifications for precision power transmission roller chains, attachments, and sprockets. Chains are categorized based on their pitch size and load-bearing capacity, with different chain numbers denoting various widths and strengths.

For mnemonic purposes, below is another presentation of key dimensions from the same standard, expressed in fractions of an inch (which was part of the thinking behind the choice of preferred numbers in the ANSI standard):

| Pitch (inches) | Pitch expressed in eighths | ANSI standard chain number | Width (inches) |

|---|---|---|---|

| 1⁄4 | 2⁄8 | 25 | 1⁄8 |

| 3⁄8 | 3⁄8 | 35 | 3⁄16 |

| 1⁄2 | 4⁄8 | 41 | 1⁄4 |

| 1⁄2 | 4⁄8 | 40 | 5⁄16 |

| 5⁄8 | 5⁄8 | 50 | 3⁄8 |

| 3⁄4 | 6⁄8 | 60 | 1⁄2 |

| 1 | 8⁄8 | 80 | 5⁄8 |

| Notes: *The pitch is the distance between roller centers. The width is the distance between the link plates (i.e. slightly more than the roller width to allow for clearance). *The right-hand digit of the standard denotes 0 = normal chain, 1 = lightweight chain, 5 = rollerless bushing chain. *The left-hand digit denotes the number of eighths of an inch that make up the pitch. *An "H" following the standard number denotes heavyweight chain. A hyphenated number following the standard number denotes double-strand (2), triple-strand (3), and so on. Thus 60H-3 denotes 3/4 inch pitch heavyweight triple-strand chain. | |||

In summary, roller chains play a vital role in transmitting mechanical power across a wide range of machinery and vehicles. Understanding their characteristics, wear factors, strength considerations, and industry standards is crucial for their effective and reliable use.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Details: www.gidi-chain.com