Basic of Roller Chain

Roller chains are commonly used in various applications, including industrial machinery, automotive engines, bicycles, motorcycles, and agricultural equipment, where reliable and efficient power transmission is required. They offer advantages such as high strength, durability, and the ability to operate under heavy loads and high speeds. Additionally, they can be easily adjusted and maintained, making them a popular choice in many mechanical systems.

The Roller Chain Structure

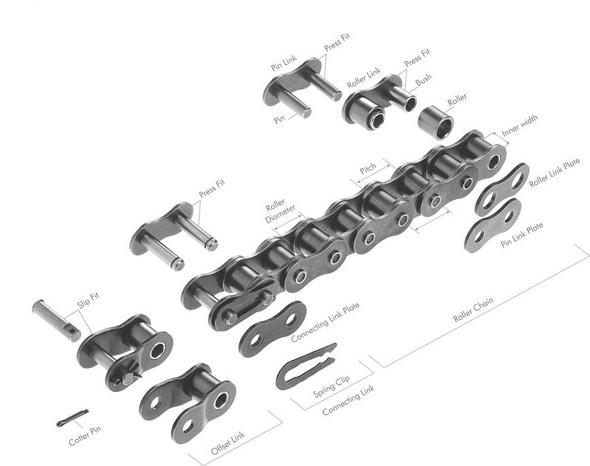

1. Three Fundamental Dimensions

Pitch, Roller Diameter, and Inner Width constitute the "Three Fundamental Dimensions of Roller Chain." When these dimensions align, roller chains and sprockets achieve dimensional compatibility.

2.Key Components

a. Link Plate

The plate endures the tension exerted on the chain, often experiencing repeated loading and occasional shocks. Consequently, it necessitates exceptional static tensile strength and resilience against dynamic loads and shocks.

b. PinSubjected to shearing and bending forces from the plate, the pin also acts as a load-bearing element with the bush during chain flexing. It requires high tensile and shear strength, resistance to bending, and endurance against shocks and wear.

c. BushExposed to various forces, notably shock loads during sprocket engagement, the bush demands extreme shock resistance. Additionally, it serves as a load-bearing component with the pin, necessitating significant wear resistance.

d. Roller

Encountering impact loads during sprocket engagement, the roller adjusts its contact point and balance thereafter. It moves between sprocket teeth and the bush, enduring compression loads. Hence, it must resist wear and possess strength against shock, fatigue, and compression. (Note: RS25 and RS35 are bush chains and lack rollers).

e. Roller LinkConsisting of two roller link plates with press-fitted bushes and rollers, facilitating rotational movement during operation. This applies to both single and multi-strand chains.

f. Pin Link and Intermediate PlateComprising two pins press-fitted into pin link plates, with an intermediate plate added for multi-strand roller chains up to size 08B (two intermediate plates for sizes above 08B). These plates are slip or press-fitted depending on the chain type.

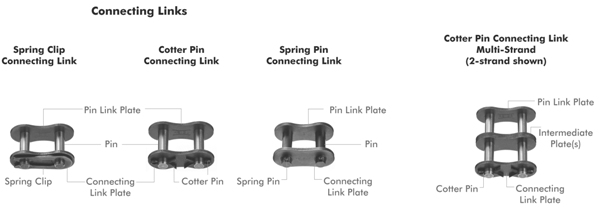

3. Assembly Components

Roller chains typically comprise inner and outer links arranged endlessly. While offset links can accommodate odd link counts, an even number is preferable. For odd counts, a two-pitch offset link is recommended over a one-pitch offset link due to its higher maximum allowable load (100% compared to 65%).

a. Connecting LinksThree types are common: slip-fit spring clip connecting links for small chains, and cotter pin and spring pin connecting links for larger chains or upon customer request.

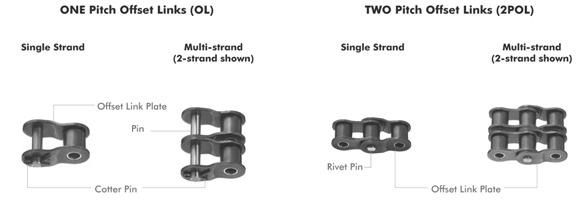

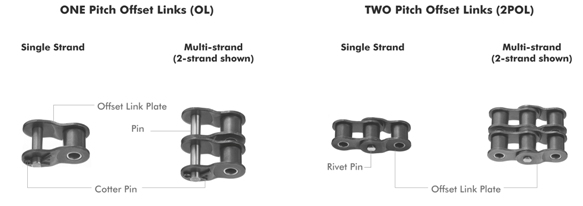

b. Offset LinksUtilized for odd link requirements, offset links come in two types:

One pitch offset link (OL): Features slip-fitted pin and plates with 35% lower fatigue strength than the chain itself.

Two pitch offset link (2POL): A combination of a roller link and an offset link riveted together, offering the same fatigue strength as the base chain. Dimension tables specify suitable roller chain types and sizes for offset links.

GIDI CHAIN LIMITED supply lots of roller chain, conveyor chain, Leaf Chain, welded chain, forged chain, Palm Oil Mill Chain, Hoisting Chain,Mine and Metallurgy Chain, etc. totaling over 3000 varieties. and 90% of chains are exported to worldwide, Which mainly export to Southeast Asia, European, North America, South America. Chains are welcomed by customers with the excellent quality. Our company owns more than 100 sets of advanced and professional manufacturing equipment, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging. Also, we have passed the ISO9001: 2015 Quality Management System Certification.

More Detail : www.gidi-chain.com